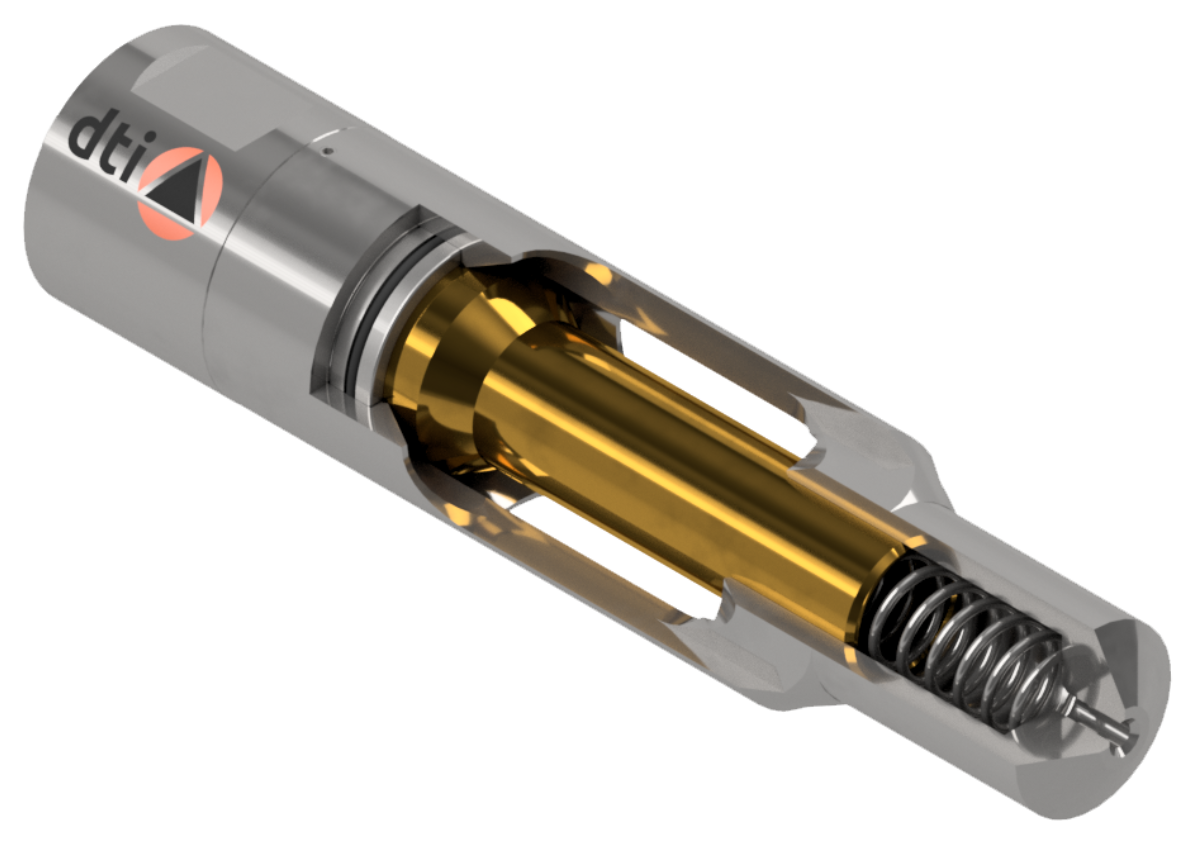

High Flow Poppet Style Injection Valve

FUNCTIONALITY

DEPLOYMENT

Wireline / Slickline

Coiled Tubing

SECTORS

Oil & Gas

CO₂, Hydrogen & Gas Storage

Geothermal

DTI's Injection Valve is run below a Lock Mandrel or DTI Bridge Plug to enable fluids to be injected into the well at high flow rates whist providing a secure well barrier to pressure from below the valve.

Whilst pumping a large flow area minimises the pressure drop across the Injection valve. In addition, high strength coatings on internal components reduce erosion and greatly increase reliability and service intervals.

The Injection Valve has been tested in demanding applications with significant solids content in the injected fluid and has reduced cost for the operator.

Features

& Benefits

- Large flow area minimises pressure drop across the valve.

- High strength material coatings and innovative design reduce flow erosion.

- Increased service intervals reduce operator cost.

- Can be run below Lock Mandrels or the DTI Bridge Plug.

| Part Number | Outside Diameter | Upper Connection | Flow Through Area | Length |

|---|---|---|---|---|

| 200HFIVBB-2 | 2.00" | 1.75-12 SLB | 0.785in2 | 11.88" |

| 225HFIVBB-2 | 2.25" | 1.75-12 SLB | 1.560in2 | 11.88" |

| 262HFIVBB-2 | 2.63" | 2.25-12 SLB | 2.000in2 | 11.88" |

| 312HFIVBB-2 | 3.12" | 2.63-12 SLB | 2.000in2 | 11.88" |