Products

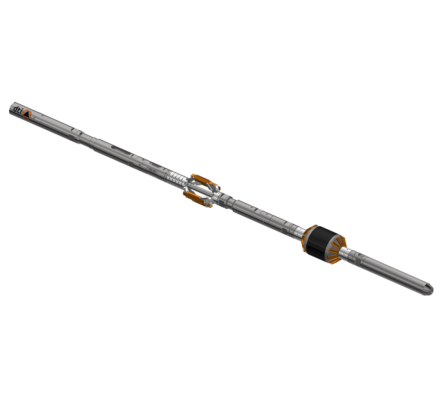

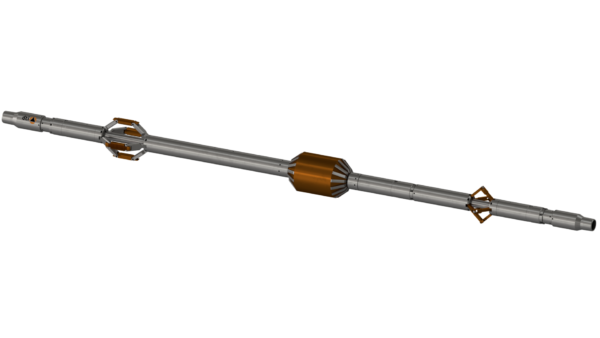

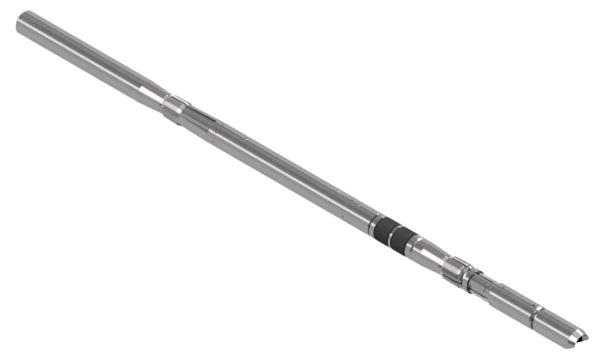

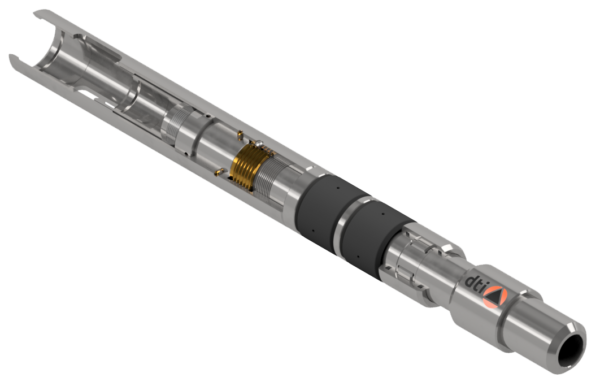

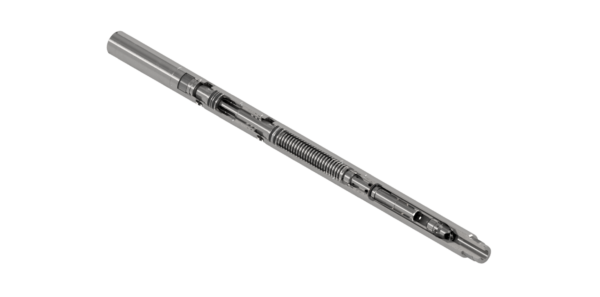

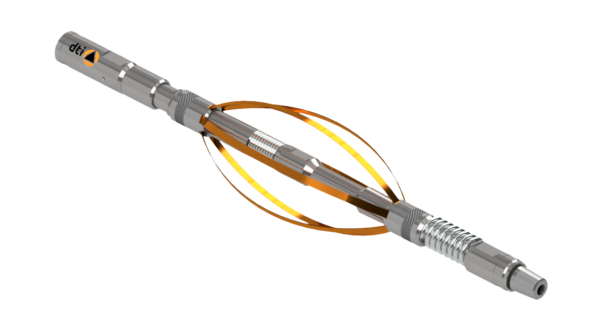

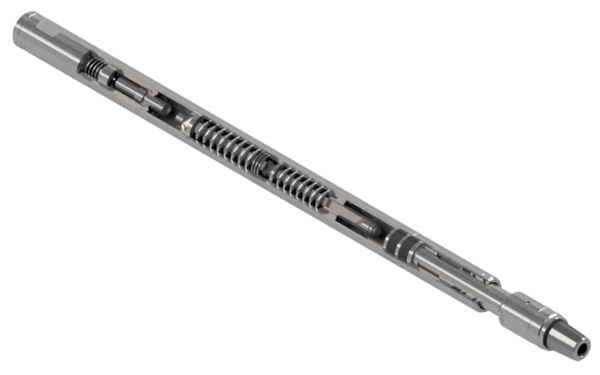

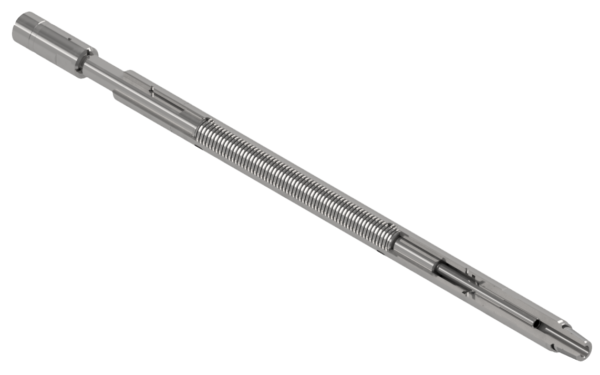

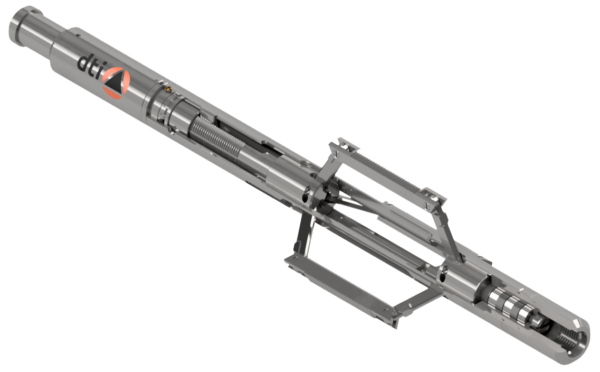

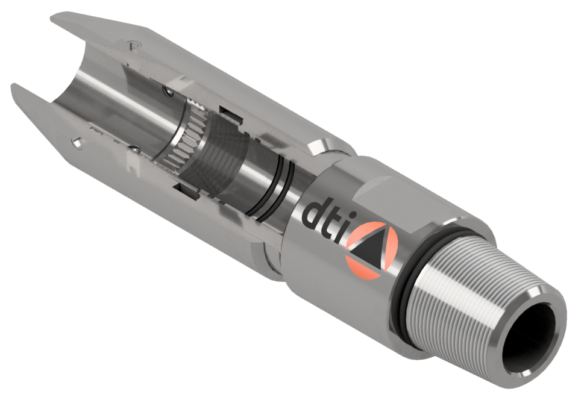

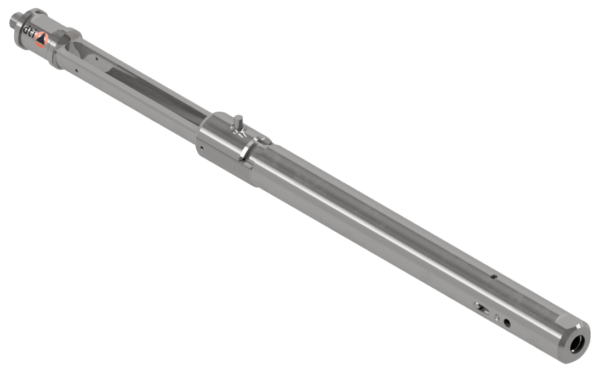

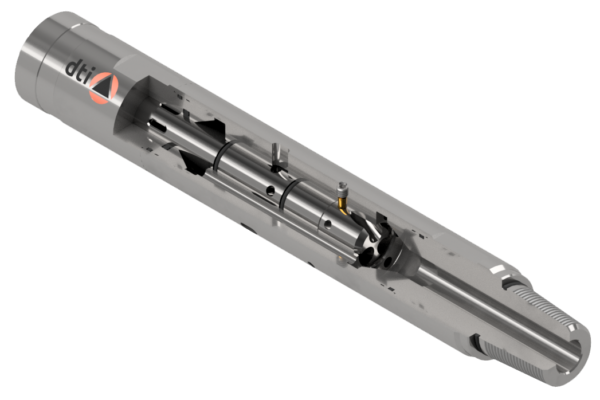

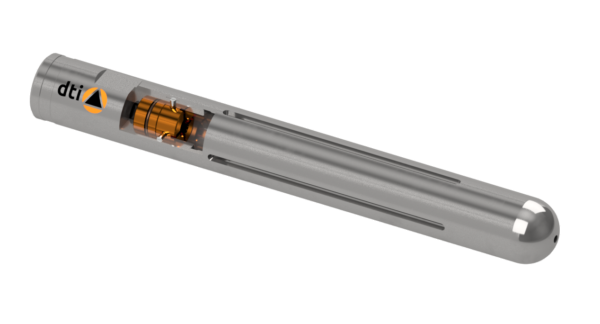

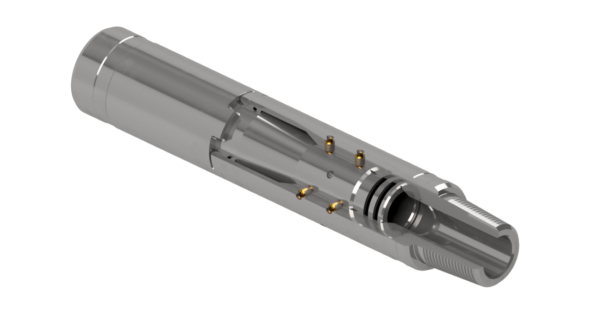

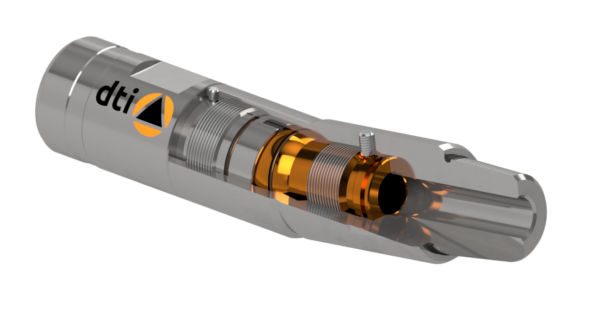

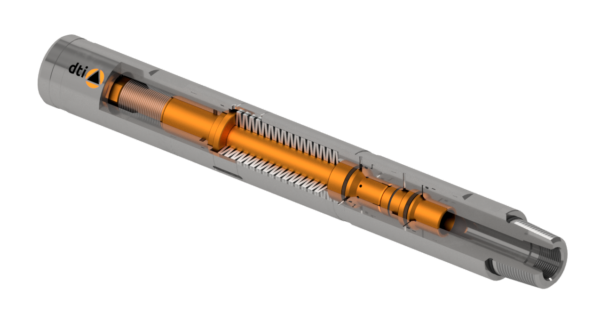

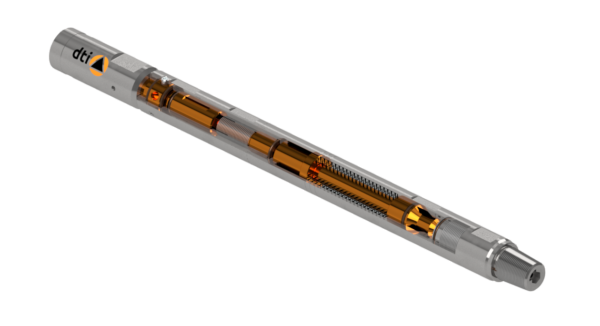

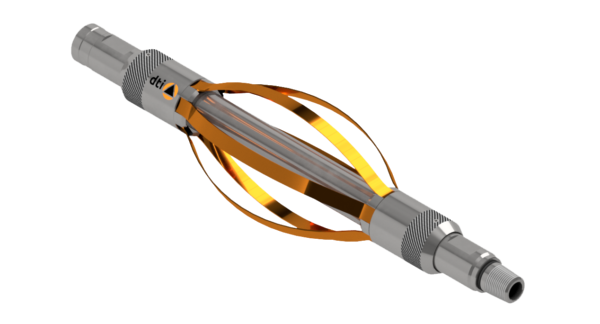

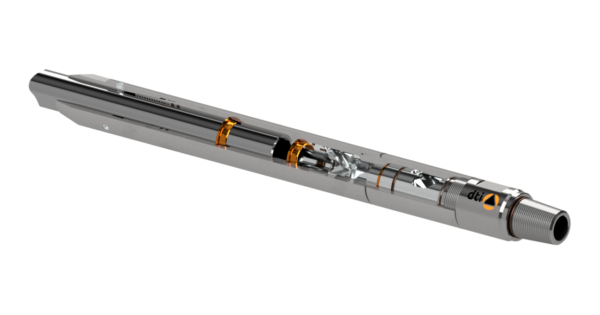

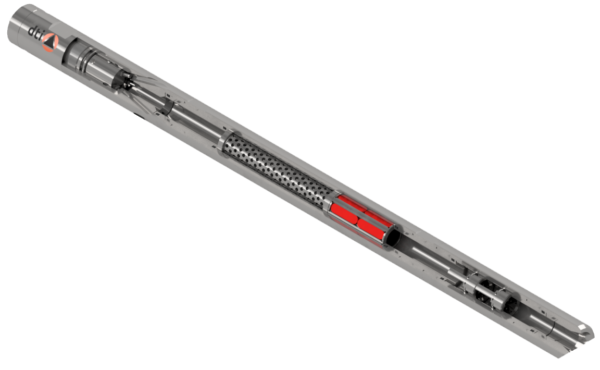

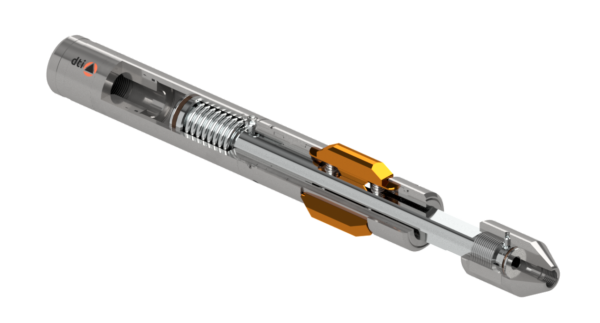

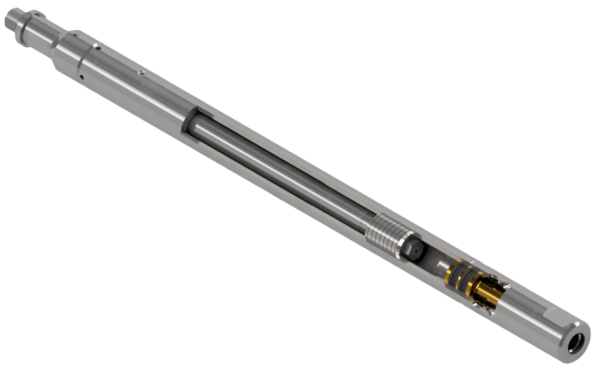

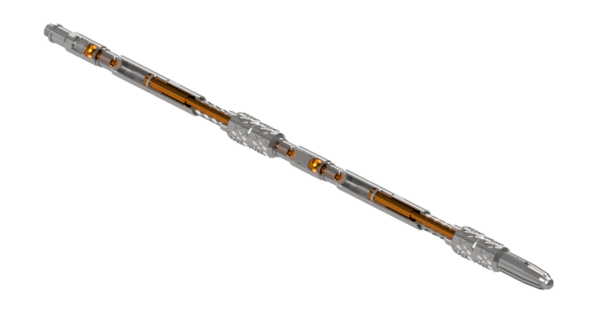

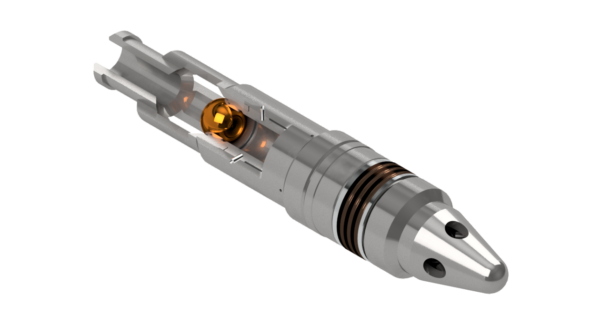

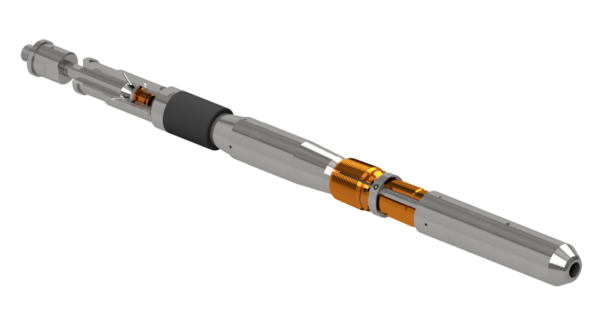

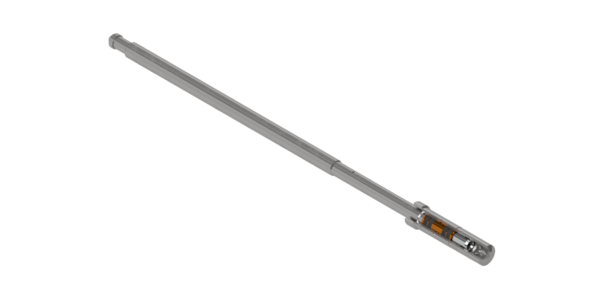

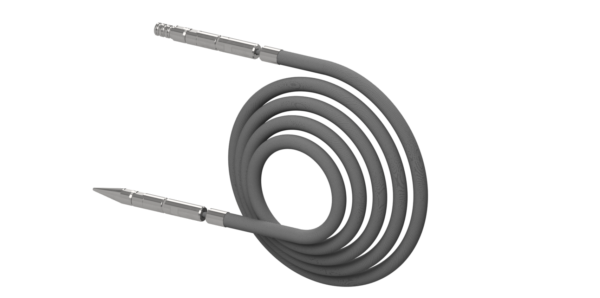

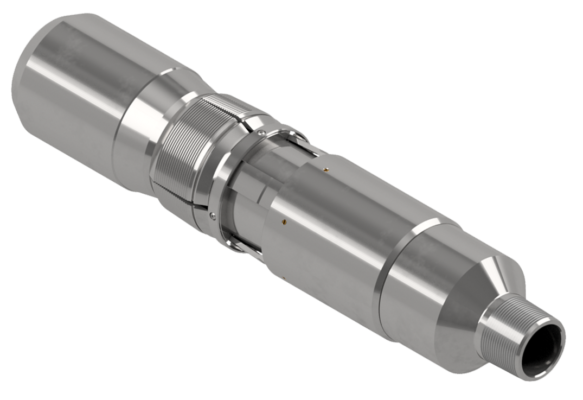

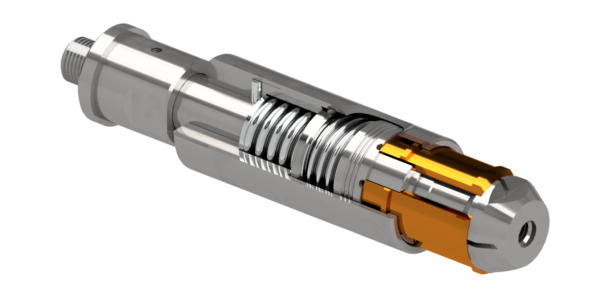

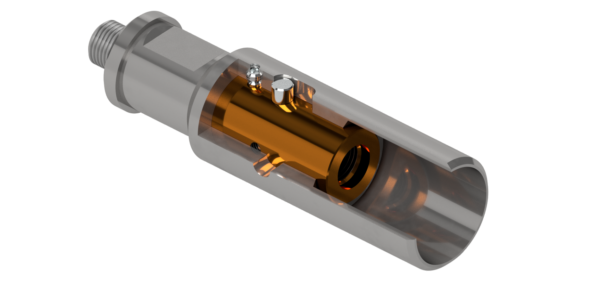

DTI supply over 10,000 coiled tubing, wireline, slickline and cable deployed tools to clients around the world.

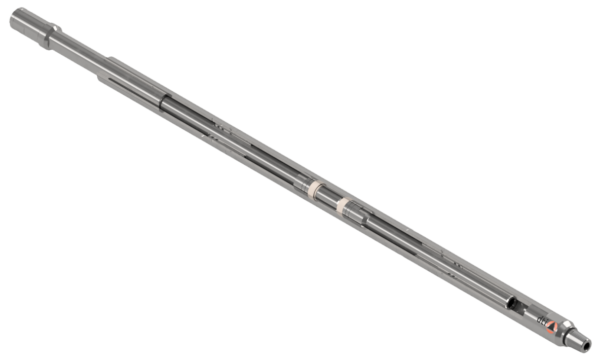

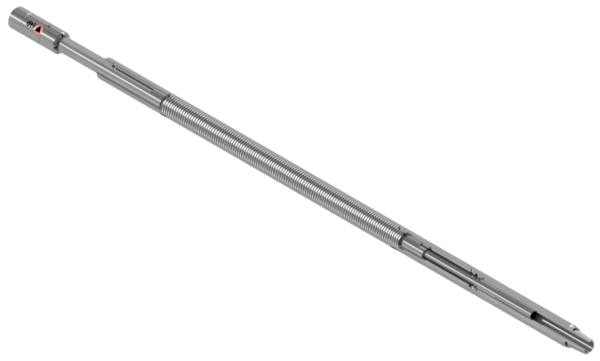

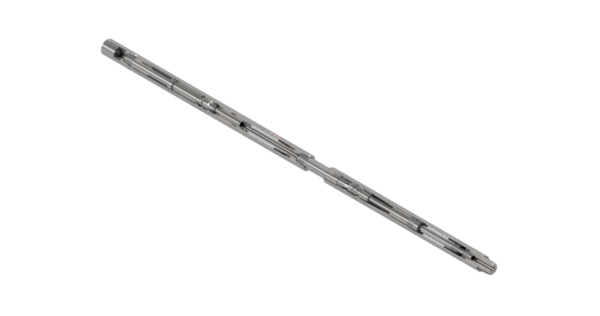

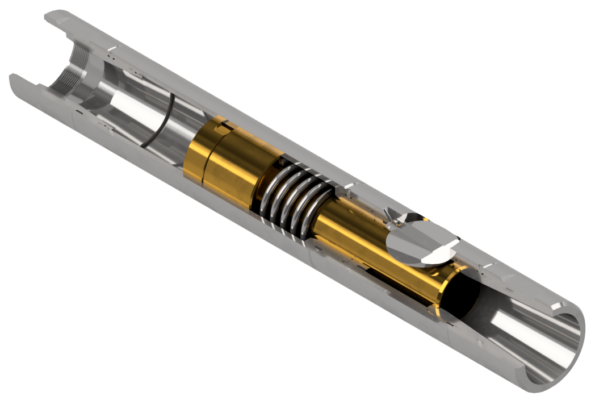

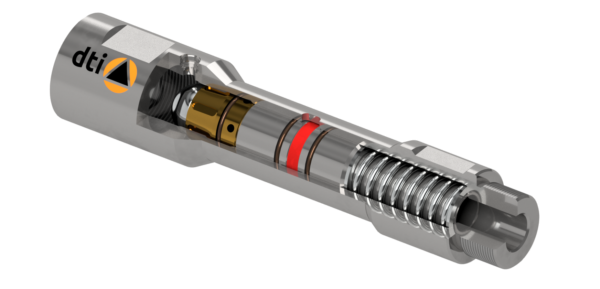

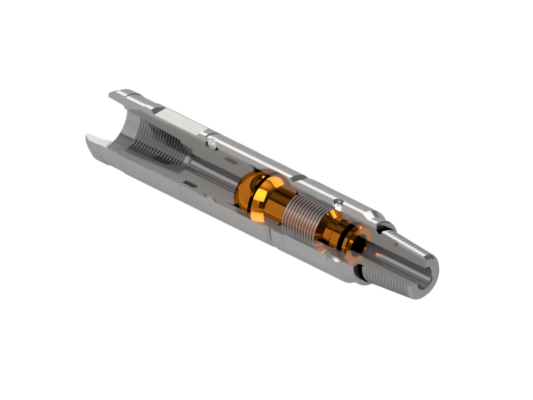

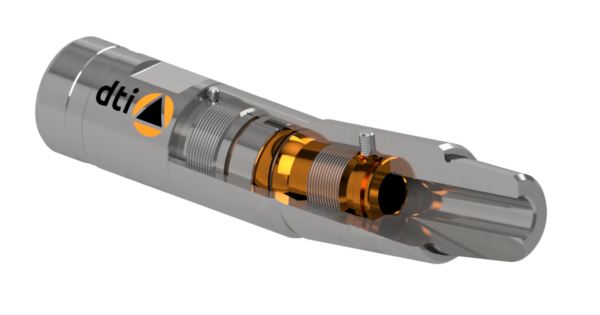

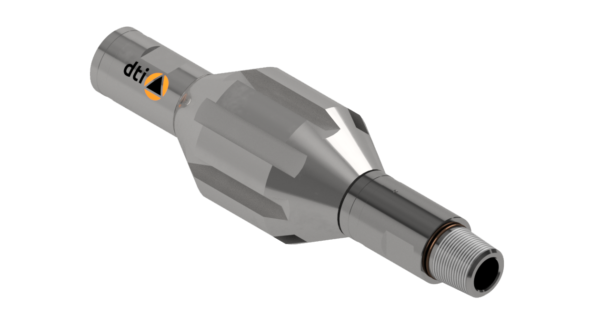

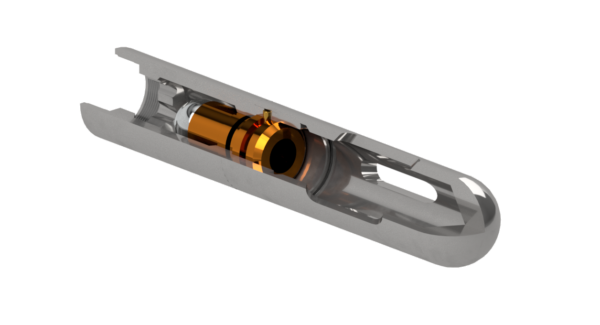

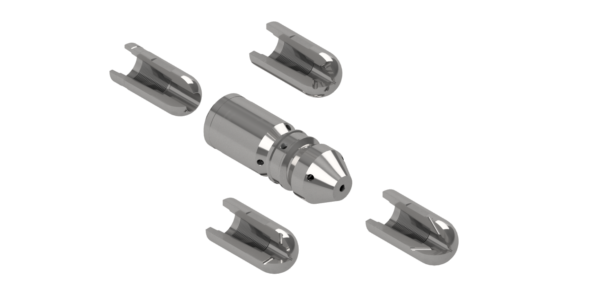

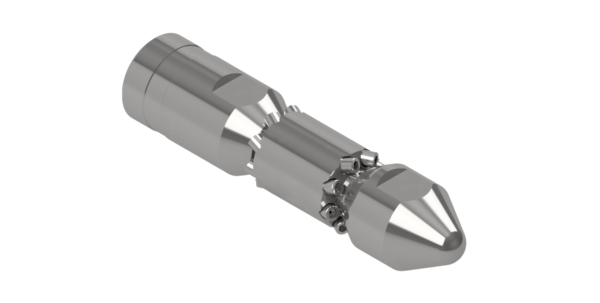

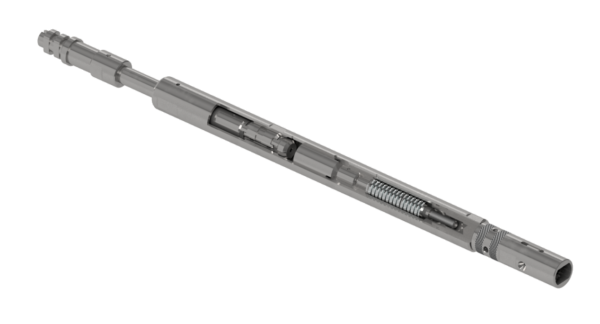

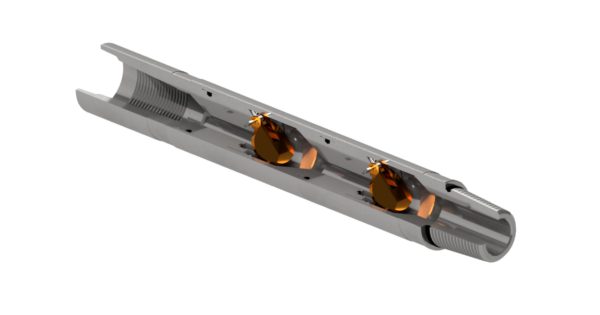

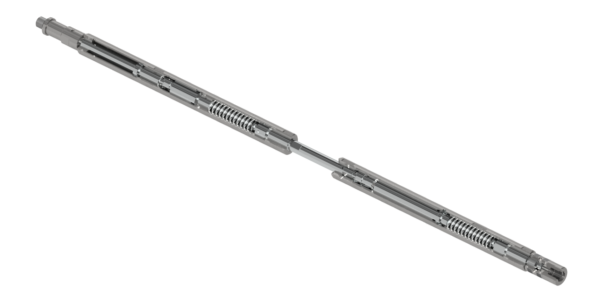

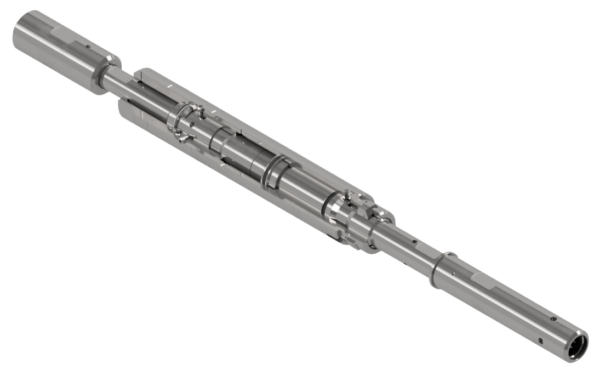

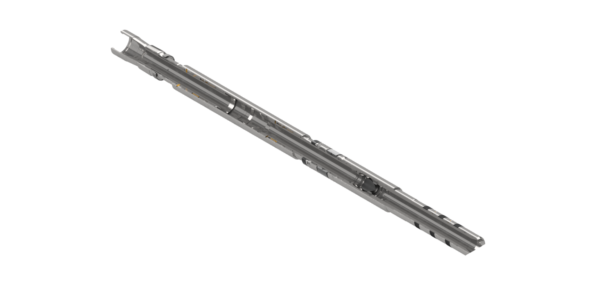

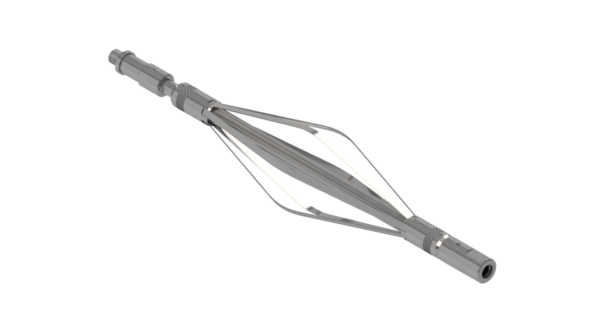

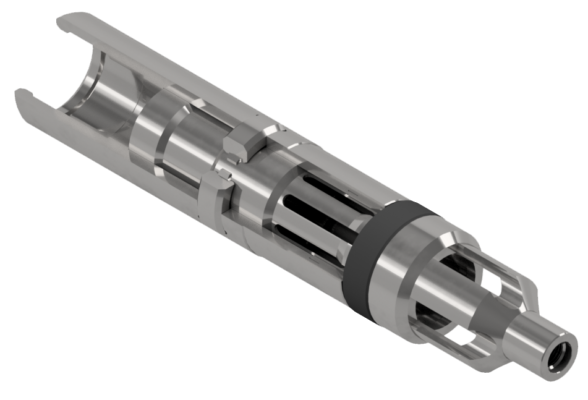

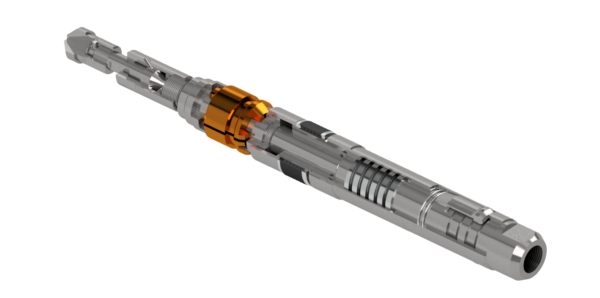

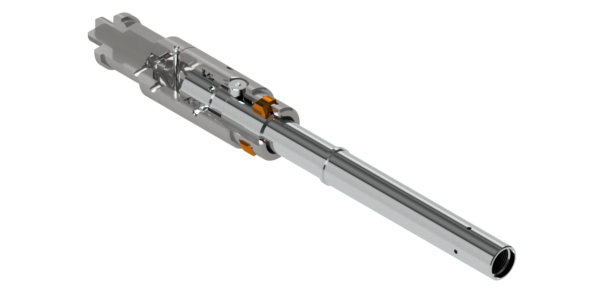

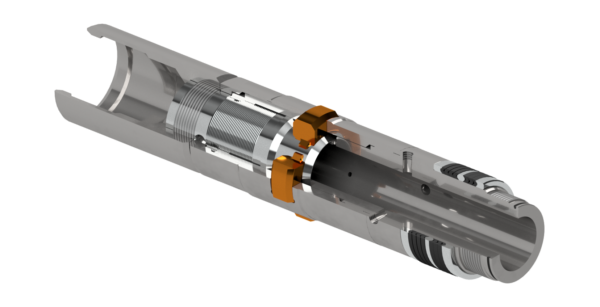

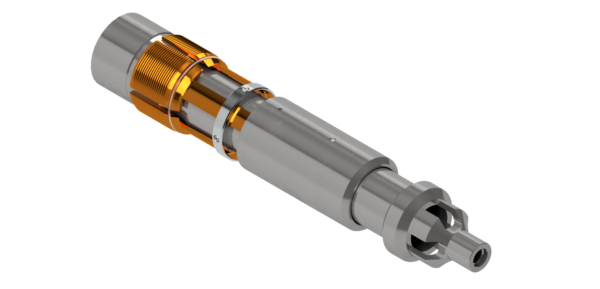

Our product search functions will help you to find tools for well intervention, production optimisation, artificial lift, well control, water shut-off, zonal isolation, workover and abandonment applications. They include safety valves, plugs, packers, packoffs, straddles, jars, connectors, motorheads, pulling tools, cleanout and fishing tools.

If you can't find what you're looking for please contact us, as not every solution is listed.

Filter By

Functionality

Deployment Type

Sectors

Featured Product Lines

Product Types

It looks like there are no products matching your search parameters.

Get in touch and we'll help you find the right product.

Solutions across the energy spectrum

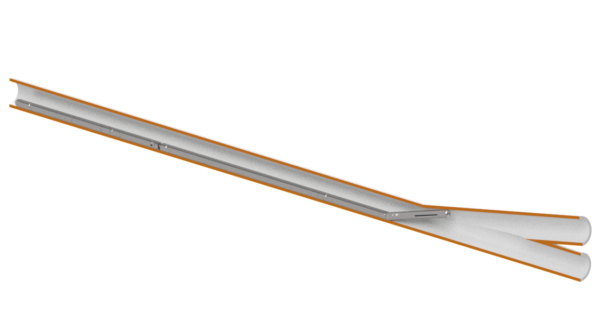

Transferring well technology from oil and gas to CCS, hydrogen and geothermal, in support of the energy transition.