Capabilities

Practical experience & technical expertise

DTI are downhole experts offering a wealth of technical knowledge in tool design, manufacturing, engineering and deployment.

We are committed to helping our customers maintain trouble-free operations, while optimising safety and efficiency and reducing cost and risk.

We can supply a wide range of specialist products, or if you’re in need of a new solution, our team of design and engineering experts are on hand to solve problems fast.

Our headquarters in Poole is home to our manufacturing and customer service base for global operations. This is supported by our R&D and technology incubator hub in Aberdeen. We also have offices in the Middle East and Asia Pacific, Eastern Europe and a network of representatives in strategic locations with regional product stockholding and rental options. This means we can spend more time in front of our clients and respond rapidly and effectively to all your enquiries.

When technical challenges arise, we are your trusted partner for fast, effective and reliable solutions, no matter where in the world you are.

Facilities and Equipment

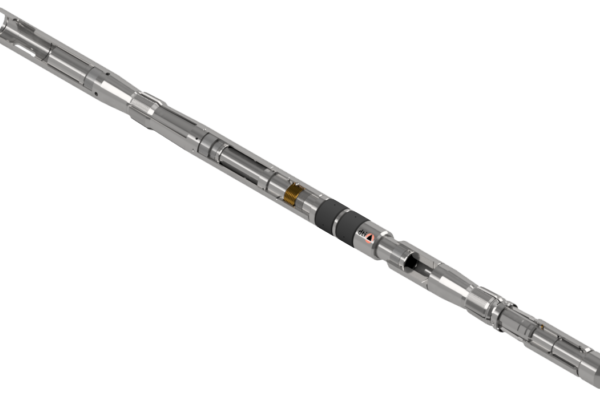

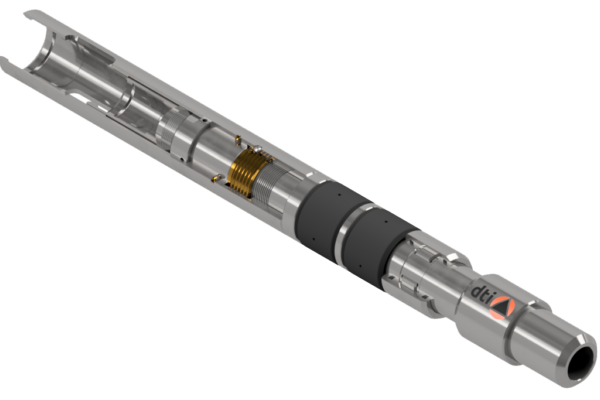

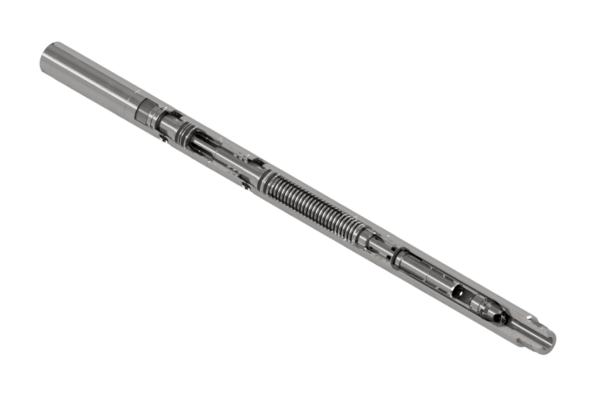

Our product design, engineering, manufacturing and certification services are supported by an extensive range of on-site facilities which include pressure test bays, flow testing and temperature testing.

DTI has developed and qualified downhole equipment including safety valves, bridge plugs and packers in accordance with API 14A and API 11D standards respectively.

We have a large R&D workshop space with a pressure test bay for hydraulic and gas testing of equipment up to 30,000 psi. Our workshop and yard areas provide the capability to perform various system integration and flow tests and to extend these in-house capabilities DTI also has access to an extensive network of specialist equipment suppliers and facilities.

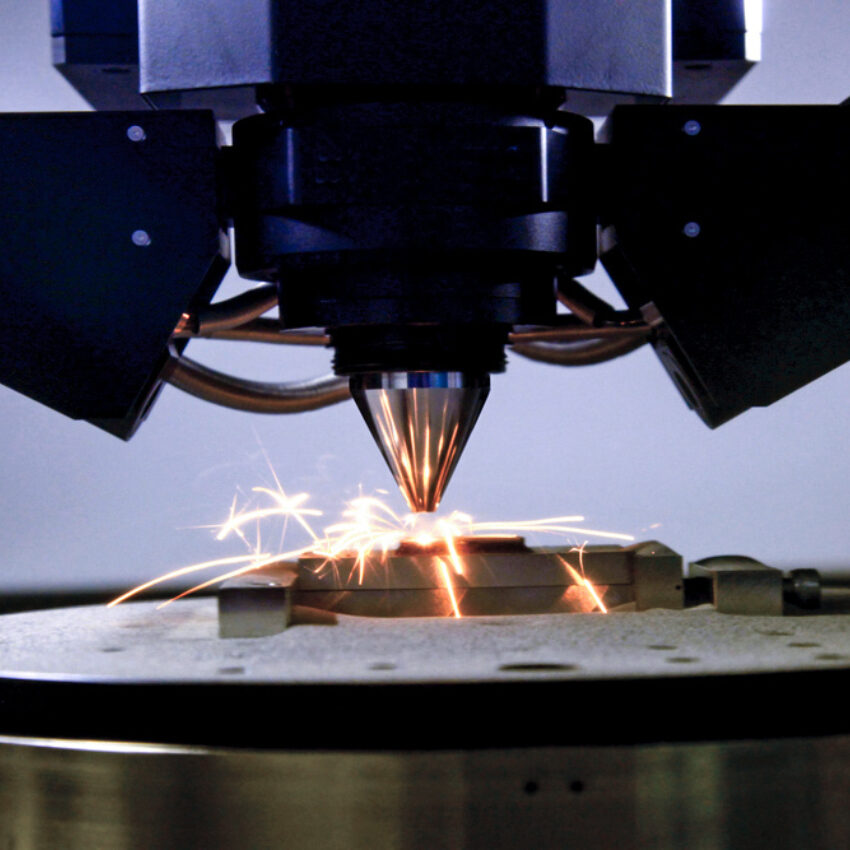

Additive Manufacturing

When considering new solutions to downhole challenges, we are careful not to be restricted by convention. We draw on learnings from other industries, such as defence and aerospace, to provide the most advanced R&D processes in the industry.

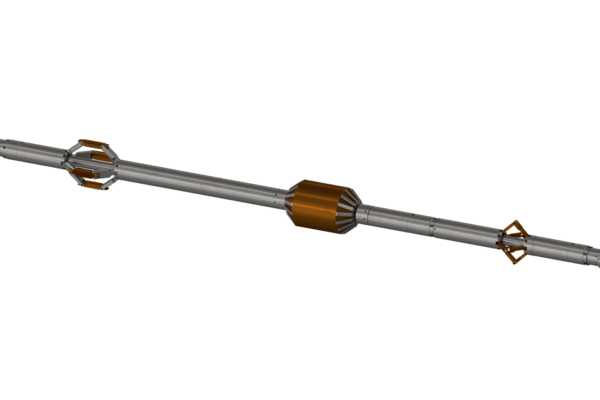

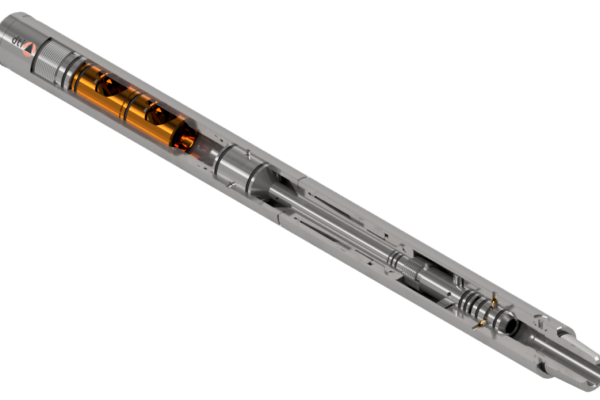

In the energy sector, we are pioneers in the use of additive manufacturing, which reduces lead times and cuts carbon emissions and waste. The technique allows intricate designs to be created with much greater intrinsic strength, more suitable for harsh downhole conditions. We use a bank of in-house 3D printers to assist with product prototyping and employ CT scanning of parts to streamline our engineering design and test methods.

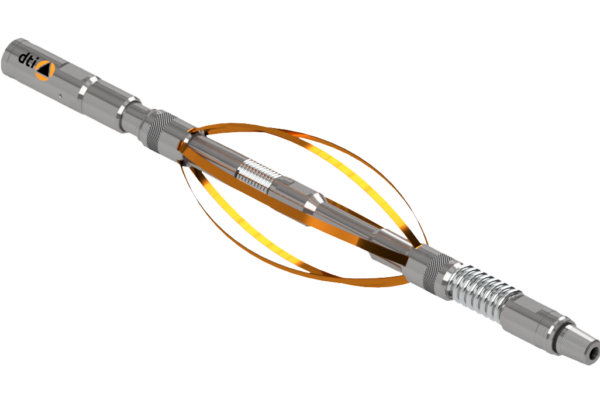

By combining our design expertise with 3D Inconel printing we have created industry-leading downhole expansion solutions. These innovative products can pass through the smallest of well restrictions to provide downhole isolation and sealing solutions at pressure ratings and expansion ratios far greater than other products. Multiple opportunities exist for future adaptation of this technology.

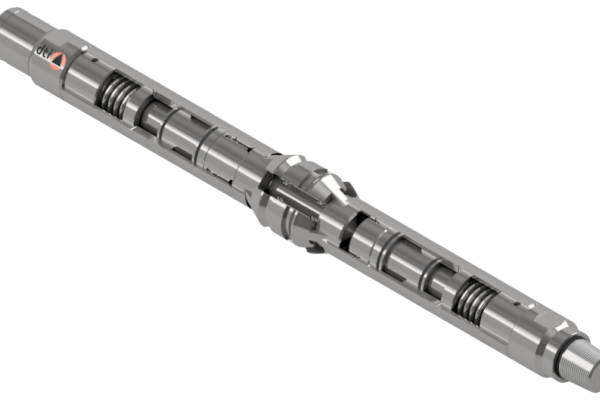

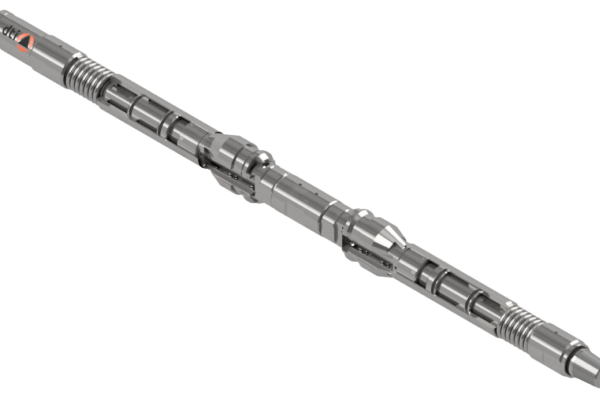

Individually Engineered Solutions

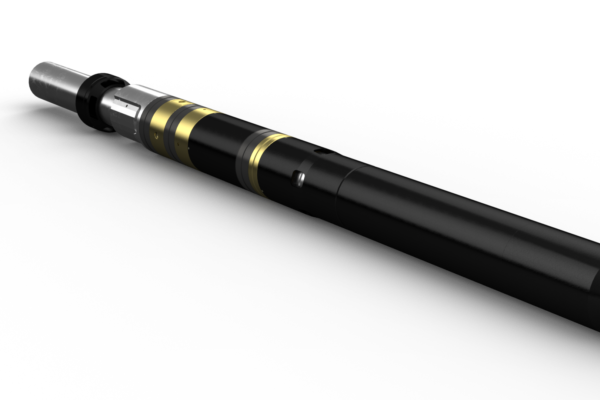

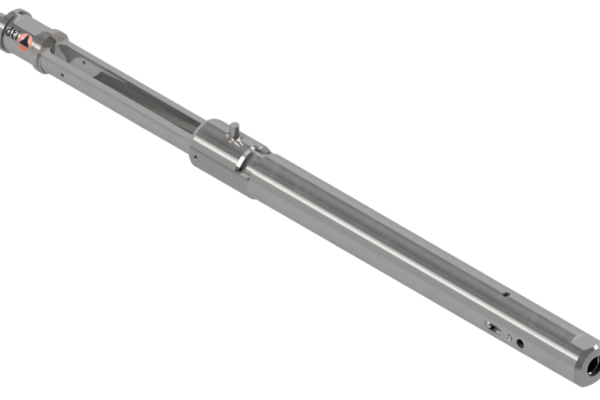

We have around 10,000 product variants available to support all your operations across the lifecycle of the well, delivering exceptional performance at every stage.

If we don’t have a product in our catalogue that’s suitable for your individual challenge, then we can adapt or engineer something to suit. Whether that’s for high-pressure gas tight resilient sealing, high temperature logging or intervening in sour and corrosive environments, we relish the opportunity of new challenges.

Our team of in-house design experts have already created several industry-leading solutions for a range of challenges including:

- Slickline deployed liner top packers.

- Emergency manipulation tools for flow control valve.

- Shifting tools for client’s unique completion valves

- Permaseal connectors for coiled tubing gas lift completion.

- Isolation valve manipulation toolstring.

- Bridge plugs and isolation tools to seal in non-standard ID completion accessories.

- Pump out completion accessory valves.

- Custom injection valve sizes for non-standard completions.

- Plug and isolation applications with high pressure and high expansion requirements.

- Custom diameter centralisers with rotational lock/ unlock option.

- Special clearance overshots.

- Fishing tools to catch treads, filter bodies and for long reach applications.

- Pulling tools for non-standard fish necks.

- Mechanical tubing punch for GRE lined tubing.

- High performance gas well pump bailers and large diameter bailers.

- Ultra heavy duty slickline and wireline fishing products.

Related Products

Get in touch today to discover more about our range of products and engineering services.

Follow us on LinkedIn and check out our news and media page for up to date activity reports and useful downloads.