Geothermal

Supporting the Energy Transition

Geothermal energy offers an excellent source of heating and power and is still largely under-developed in terms of its possible level of contribution as an energy resource. Challenges include the high relative cost of new projects versus the commodity return, plus the fact that well sites are location specific. However, this important sector is an increasing focus for the global energy industry as we diversify our energy portfolio to improve security of supply and move towards more sustainable practices.

We are committed to supporting energy diversification through skills and technology transfer

Large-scale heat and power production plants use large diameter geothermal wells to produce large fluid volumes, often from the open hole or through a slotted liner, rather than tubing. Most low temperature geothermal reservoirs will not produce without pumping so line shaft or electric submersible pumps (ESPs) are installed to increase the flow rate or to pressurise the fluid to avoid gas release.

Brine quality varies greatly in geothermal production and can be highly corrosive with high levels of dissolved solids in high-temperature systems. Maintaining the produced water under pressure, especially where there is high carbon dioxide content, can reduce corrosion and scaling.

Corrosion can be so severe that more advanced downhole materials are required and even titanium casing becomes economic. Scaling can lead to frequent workovers to replace pumps and other downhole equipment and to remove the scale using jetting or milling. The requirement for a cement sheath to surface means that if circulation zones become unproductive, they must usually be plugged before cementing using seals that can withstand high pressure and temperature cycling.

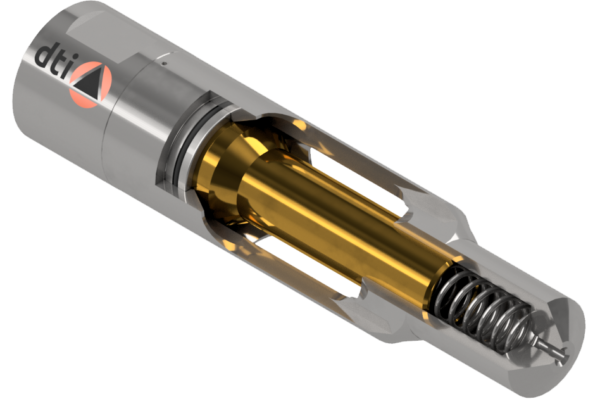

While high temperature in the produced water of geothermal applications is generally regarded as 150 degrees Celsius, DTI has proven technology, design and engineering capabilities for high temperature and high pressure (HPHT) applications up to 340 degrees Celsius.

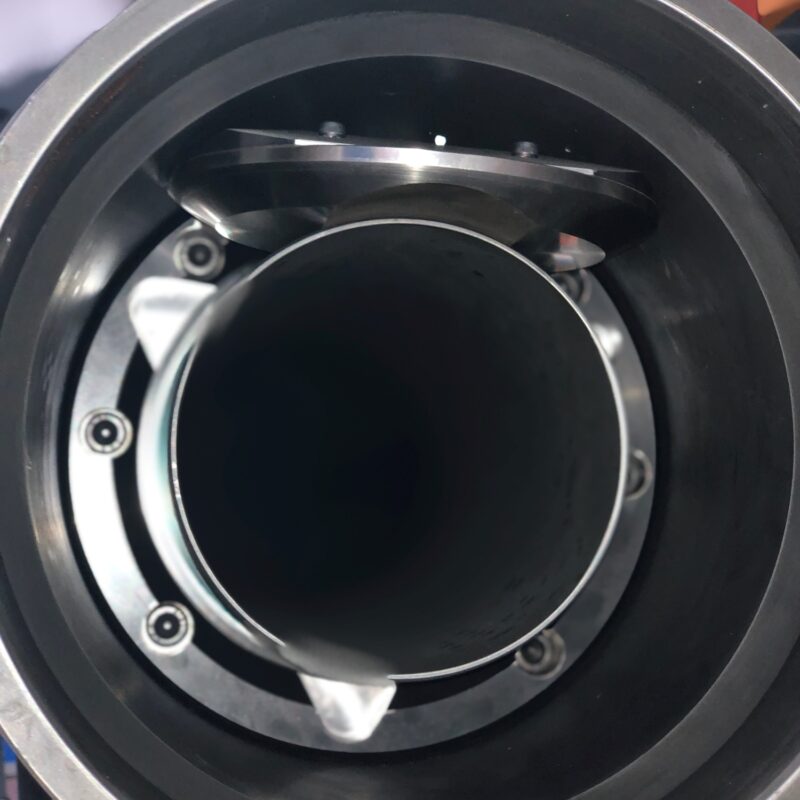

Our high temperature valve that can operate at 340 degrees C, incorporates features to prolong control fluid life and full metal-to-metal seals. We also have a range of plugging, jetting and clean-out tools plus downhole safety valves which can be retrofitted with cable deployed ESPs.

We are committed to supporting this transition and our technology range has many suitable products already tried and tested in high pressure, high temperature and corrosive environments that can be applied to new sectors. If we don’t have the exact specification you need, then we are confident that we can develop something to suit, so please get in touch with our team to discuss your requirements.

Featured Product Lines

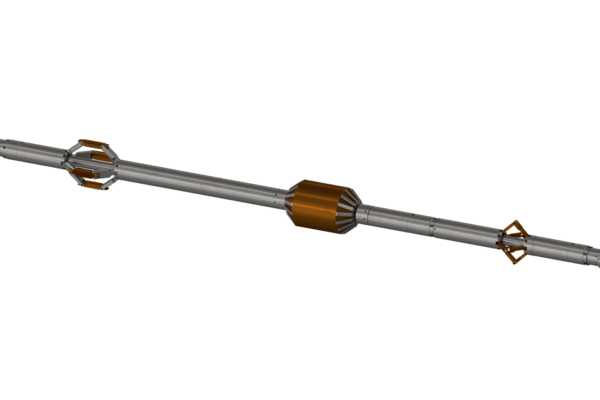

PermaSeal

Ultra-High Expansion (UHX) Sealing Solutions

Extreme Temperature Safety Valve

Product Support,

Training & Resources

Our downhole tools are designed for simplicity of maintenance and are provided with clear product guides, videos and training to support your own field operation and redress. However, when expert maintenance is required, we are at your side with experienced specialists available to service, test and requalify tools at either our facilities or your own.

Related Products

If you have a requirement for downhole technology in the geothermal sector, please get in touch with our team.

Our team are ready to take your call and can talk through our existing range of products or discuss new R&D and engineering solutions.