External Torque Through Slip Connector

FUNCTIONALITY

DEPLOYMENT

SECTORS

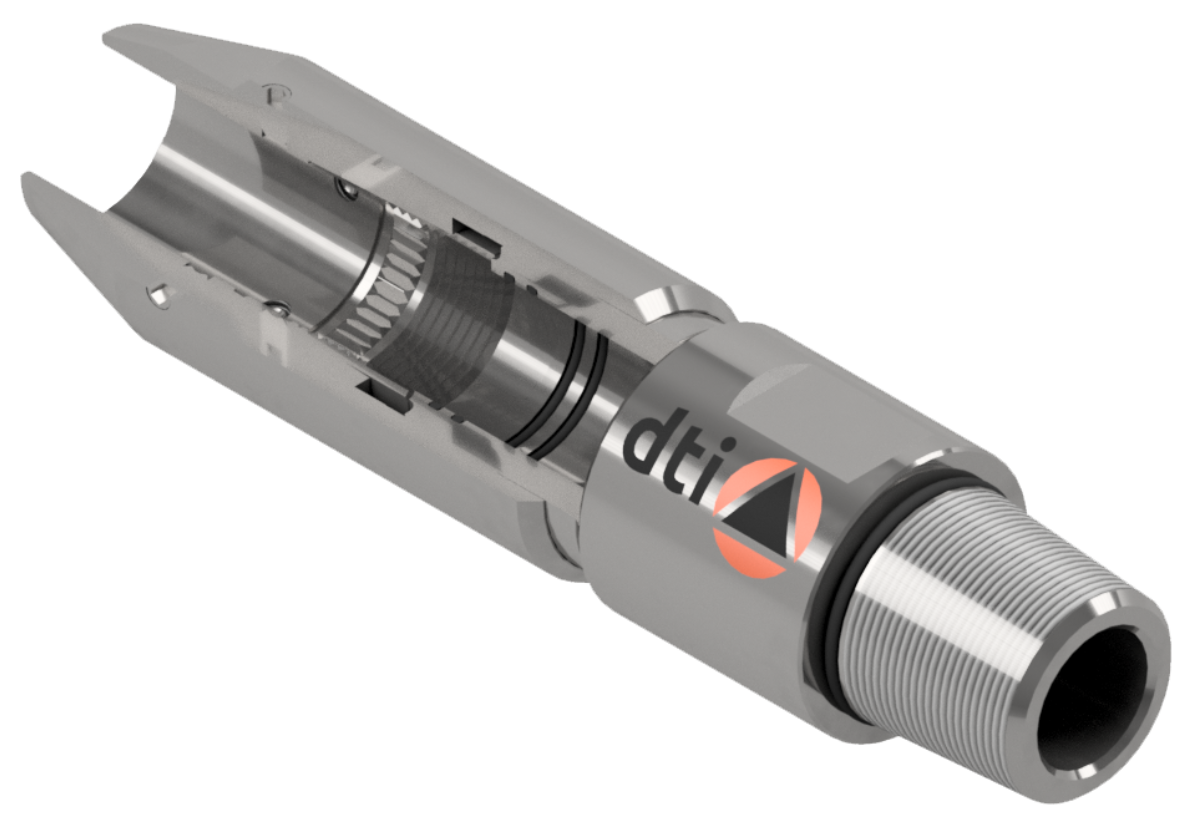

The DTI External Torque Thru Slip Connector is a very high strength connector which is easy to make up and is also suitable for demanding milling operations.

The DTI Torque Thru Slip Connector features a torque resistant Slip that is keyed to the Connector Lower Body. Making up the DTI Torque Thru Slip Connector at the well site is both fast and safe with the makeup torque applied locking the connector securely to the Coiled Tubing.

Increasing the tensile and torque loads applied to the DTI Torque Thru Slip Connector increases the force with which the rotationally locked tapered Slip grips the Coiled Tubing. The DTI Torque Thru Slip Connector is therefore rated to exceed the maximum torque from motors of the same toolstring size and can be relied upon for the most demanding applications.

Features

& Benefits

- Slips bite into the coiled tubing.

- Axial tooth to prevent rotation.

- Compact.

- Double Viton O-Ring seals.

- Easy make up requiring minimal Coiled Tubing preparation.

| PART NUMBER | COILED TUBING SIZE | OUTSIDE DIAMETER | INSIDE DIAMETER | THREAD CONNECTION |

|---|---|---|---|---|

| SCT125169AC08 | 1 1/4" | 1.688" | 0.750" | 1.00 AMMT |

| SCT150212AC09 | 1 1/2" | 2.125" | 1.000" | 1.50 AMMT |

| SCT175238AC09 | 1 3/4" | 2.375" | 1,000" | 1.50 AMMT |

| SCT200288AC23 | 2" | 2.875" | 1.375" | 2.38 PAC |

| SCT238288AC23 | 2 3/8" | 2.875" | 1.375" | 2.38 PAC |