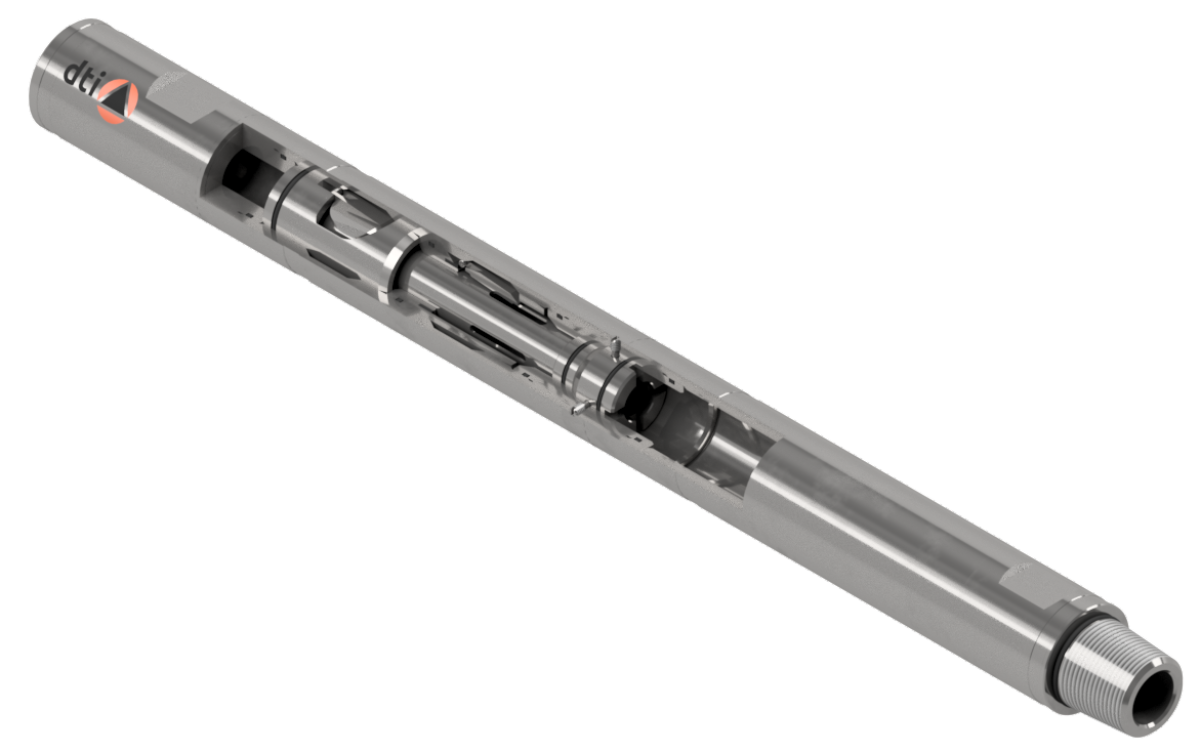

Twin Flapper Check Valve with Lock Out Sleeve

FUNCTIONALITY

DEPLOYMENT

SECTORS

The DTI Twin Flapper Check Valve with Lock Out Sleeve allows the check valve to be run in hole in the open position to enable the reverse circulation of fluid from the well through the coiled tubing. When required, a drop ball can be used to shear out the lockout sleeve into an integral catcher sub below. The valve will then be activated as a conventional dual barrier within the tool string against well fluid back flow through the coiled tubing. It is robust, reliable, easy to redress and rated to 10,000PSI.

Two flapper cartridge sub-assemblies fit into the main valve body to provide an effective dual barrier. The flappers have combined elastomeric/ metal seating, providing efficient low- and high-pressure sealing, combined with simple redress.

All DTI’s motorheads and flapper check valves use our single-piece flapper cartridge design – pioneered at DTI and now copied throughout the industry for ultimate reliability and reduced leak paths and easier redress.

All these cartridges are factory pressure tested and are available to suit most housings and applications.

Features

& Benefits

- Uses DTI pioneered single piece flapper cartridges for reduced leak paths and easier redress.

- Dual Barrier through two cartridge assemblies.

- Metal-to metal sealing on flapper against cartridge.

- Combined low- and high-pressure sealing feature.

- Easy to redress by replacing cartridge body.

- Spare cartridges can be supplied fully assembled and tested.

- Integral catcher sub so nothing is left behind.

- All Twin Flapper Check Valve with Lock Open Sleeves are rated to 10,000 psi and 200 C.

Deployment and Operation

- Flapper Cartridges are held open to allow reverse circulation.

- When a conventional well barrier is required then drop a ball and over pressure to shear the lock out sleeve.

- Over pressure to shear can be set at surface by selecting shear pins.

| Part Number | OD | ID | Drop Ball | Length | Tensile Rating | Threads |

|---|---|---|---|---|---|---|

| TFCVL150AC08 | 1.500 | 0.25” | 0.312” | 22.0” | 40,000 | 1.00” AMMT |

| TFCVL175AC08 | 1.750” | 0.40” | 0.438” | 22.0” | 50,000 | 1.00” AMMT |

| TFCVL212AC09 | 2.125” | 0.50” | 0.625” | 24.4” | 80,000 | 1.50” AMMT |

| TFCVL238AC09 | 2.375” | 0.63” | 0.750” | 32.0” | 80,000 | 1.50” AMMT |

| TFCVL288AC23 | 2.875” | 0.75” | 0.812” | 33.8” | 124,000 | 2-3/8 PAC |

| TFCVL312AC23 | 3.125” | 0.75” | 0.812” | 33.8” | 124,000 | 2-3/8 PAC |

| TFCVL350AC12 | 3.500” | 1.25” | 1.500” | 36.3” | 150,000 | 2 3/8” EUE |