Tubing Perforator

FUNCTIONALITY

DEPLOYMENT

SECTORS

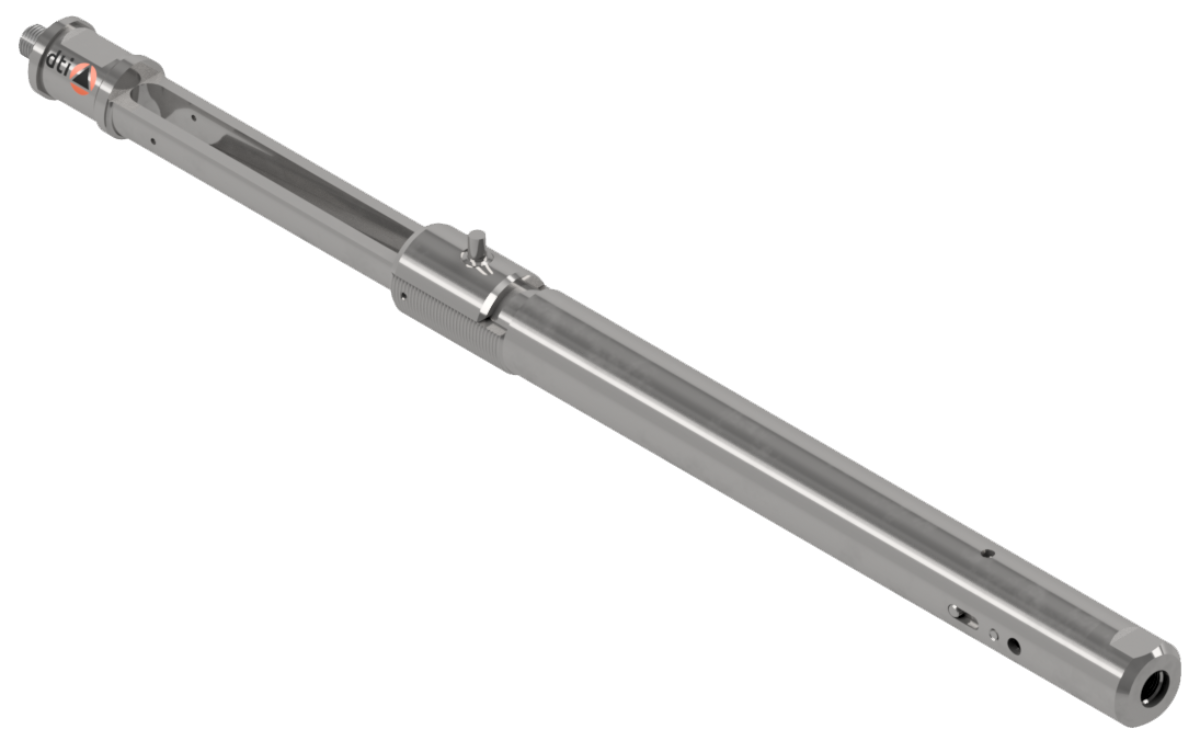

The DTI Tubing Perforator is a mechanically operated punch assembly which is designed to make a single perforation in the production tubing wall per wireline run.

This is desirable when a circulation flow path needs to be opened up from the tubing to the annulus to enable extra production, for example, or to kill a well.

The DTI Tubing Perforator has an outer body which houses a punch assembly. The punch runs in a moving tapered track, such that upward jarring will expand it through the tubing wall. Continued jarring will then retract it in the same track.

Slimline versions of the tubing perforator are available for applications where there are restriction in the tubing string or the tubing string is reduced in inside diameter by Glass Reinforced Epoxy (GRE) liner.

A modified version of the 3 ½” Tubing Perforator is available with a 0.50” punch diameter.

Features

& Benefits

- Longer punches available for softer tubing.

- Enables a single hole to be punched during a wireline run.

- Available as standard for 2-3/8”, 2-7/8”, 3-½”, 4”, 4-½”, 5” & 5-½” production tubing.

- Field proven mechanical tubing punch mechanism.

- Operates mechanically via wireline upward jarring in order to complete the perforating cycle.

- Incorporates a safety release abort mechanism by downward jarring.

- Slimline versions for GRE Tubing.

Applications

Circulation of Kill

Provides access to the casing annulus to circulate or kill the well.

Gas Lift

Provides annular communication for gas lift straddles.

Injection

Opens up the annulus for separated water injector wells

Emergency Communication

Provides emergency annular communication in the case of Sliding Side Doors failing to open.

Production

Bring in additional productive zones or permit production through a plug tail pipe that cannot be opened using regular methods.

Cementing

Permits cement squeeze operations.

| PART NUMBER | OUTSIDE DIAMETER | PUNCH DIAMETER | THREAD CONNECTION | LENGTH | TUBING/CASING SIZE |

|---|---|---|---|---|---|

| 166DTITP | 1.25” | 0.250” | 5/8-11 UN | 20.5” | 1.66" 2.3/2.4 LB/FT |

| 190DTITP | 1.47” | 0.312” | 15/16-10 UN | 22.7” | 1.90" 2.75 LB/FT |

| 206DTITP | 1.63” | 0.312” | 15/16-10UN | 22.7” | 2 1/16" 3.4 LB/FT |

| 238DTITP | 1.84” | 0.375” | 15/16-10UN | 30.5” | 2 3/8" 4.0/4.6 LB/FT |

| 278DTITP | 2.19” | 0.375” | 15/16-10UN | 30.9” | 2 7/8" 6.4/8.6 LB/FT |

| 350DTITP | 2.69” | 0.438” | 1 1/16-10UN | 30.9” | 3 1/2" 7.7/10.2 LB/FT |

| 350DTITP-050 | 2.69” | 0.500” | 1 1/16-10UN | 30.9” | 3 1/2" 7.7/10.2 LB/FT |

| 450DTITP | 3.65” | 0.500” | 1 1/16-10UN | 30.9” | 4 1/2" 11.6/12.6 LB/FT |

| 500DTITP | 4.28” | 0.500” | 1 1/16-10UN | 30.9” | 5” 15 LB/FT |

| 550DTITP | 4.77” | 0.500” | 1 9/16-10UN | 30.9” | 5 1/2" 17 LB/FT |

| 238DTITP-S | 1.62” | 0.375” | 15/16-10UN | 30.5” | 2 3/8" 4.0/4.6 LB/FT |

| 278DTITP-S | 2.00” | 0.375” | 15/16-10UN | 30.9” | 2 7/8" 6.4/8.6 LB/FT |

| 350DTITP-S | 2.50” | 0.438” | 1 1/16-10UN | 30.9” | 3 1/2" 7.7/10.2 LB/FT |

| 450DTITP-S | 3.44” | 0.500” | 1 1/16-10UN | 30.9” | 4 1/2" 11.6/12.6 LB/FT |

| 550DTITP-S | 4.60” | 0.500” | 1 9/16-10UN | 30.9” | 5 1/2" 17 LB/FT |

We offer optional equipment, alternative sizes, materials and thread connections. Please contact us for more information.