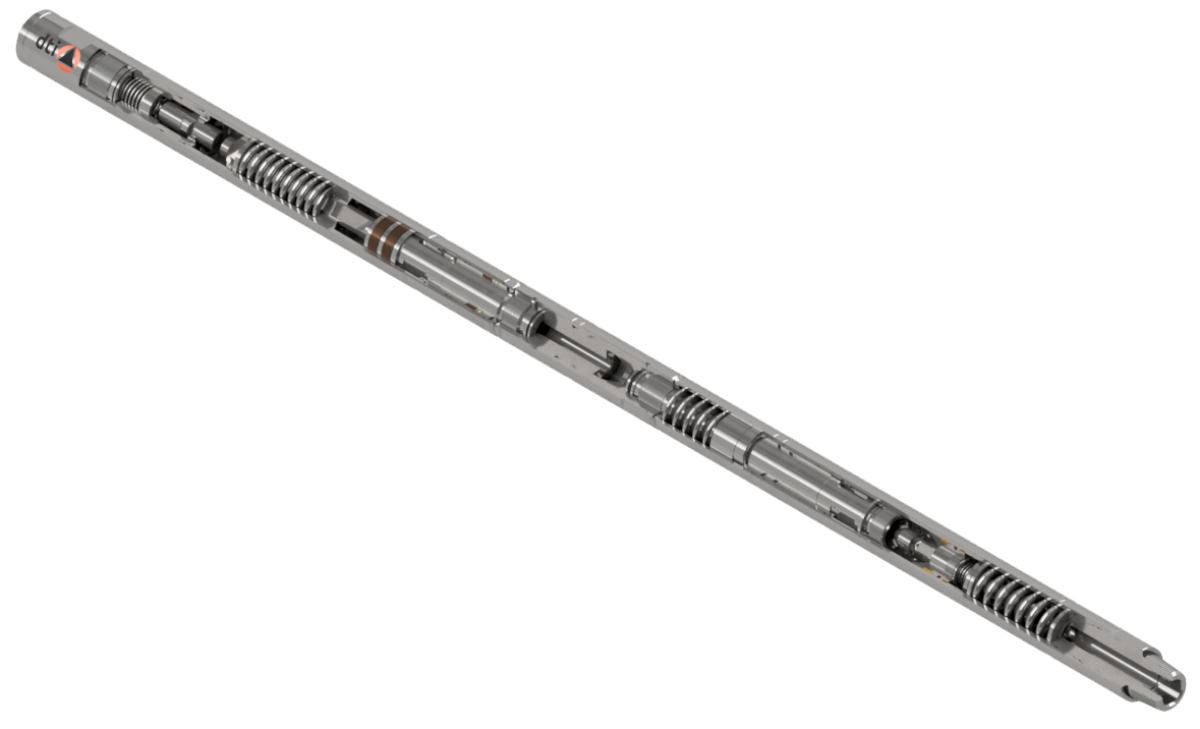

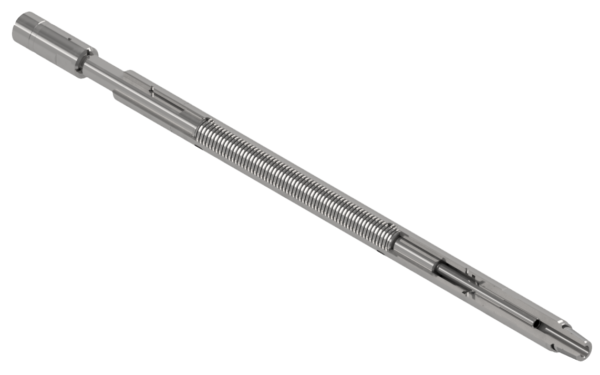

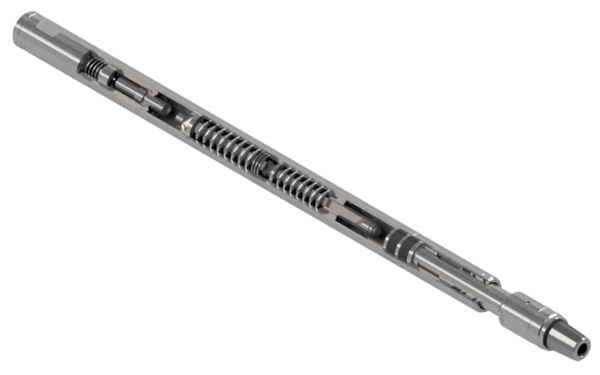

Hammerhead Bi-Directional Impact Hammer

DEPLOYMENT

SECTORS

The Hammerhead Bi-Directional Impact Hammer delivers a controllable high frequency up or down impact to a downhole device.

The frequency and magnitude of the impacts delivered are controlled via the flow rate and applied force. A short length and the ability to configure the Impact Hammer as up only, down only or bi-directional make the Hammerhead suitable for many applications including shifting sleeves, breaking disks, pulling plugs, scale removal, cleanouts, tubing swaging and broaching. The ability to deliver high frequency impacts with low applied force and without the necessity to cycle the Coiled Tubing make the Hammerhead an attractive alternative to using a Jar.

A Hammerhead Accelerator Tool is also available to optimise the performance of the Hammerhead when there is little effective length of Coiled Tubing above the Hammer. The DTI Hammerhead Bi-Directional Impact Hammer is manufactured from high grade materials and has an operating mechanism that does not rely on elastomer performance, making the tool suitable for corrosive and high temperature environments.

Features

& Benefits

- Compact length

- High frequency controllable up and down impacts

- Can be configured as Up Hammer, Down Hammer or Bi-Directional Hammer

- Reduces Coiled Tubing fatigue compared with jarring

- Mechanism does not rely on elastomeric seals making it suitable for use in corrosive and high temperature wells.

- Bits such as ballistic button bits, chisel bits and star bit chisels are available on request.

| Part Number | Outside Diameter | Length | Impact Frequency Per Minute | Thread Connection |

|---|---|---|---|---|

| FHB169BB08 | 1.688” | 52.0” | 60-600 | 1.00 AMMT |

| FHB212BB09 | 2.125” | 53.5” | 60-600 | 1.50 AMMT |

| FHB288BB23 | 2.875” | 55.0” | 60-600 | 2.38 PAC |

We offer optional equipment, alternative sizes, materials and thread connections. Please contact us for more information.