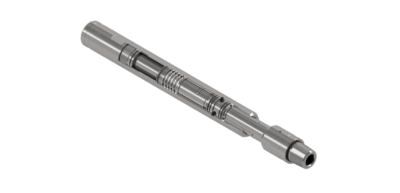

Milling Circulation Valve

FUNCTIONALITY

DEPLOYMENT

SECTORS

DTI's Coiled Tubing Milling Circulation Valve provides a constant fluid flow path to the motor or BHA during milling operations while providing a means of high volume circulation to the annulus when required.

Designed to be run above a motor, the DTI Milling Circulation Valve enables unlimited switching between milling operations and high flow rate clean out. This increases the flow rate available to effectively remove debris from the well and prevents motor damage during hole cleanout.

The DTI Milling Circulation Valve is activated by picking up from bottom, and briefly over pressuring the tool string to above the valve pressure setting, to release a hydraulic lock. Closing the Milling Circulation Valve is achieved simply by reducing the flow rate to normal milling rates and sitting back down.

Features

& Benefits

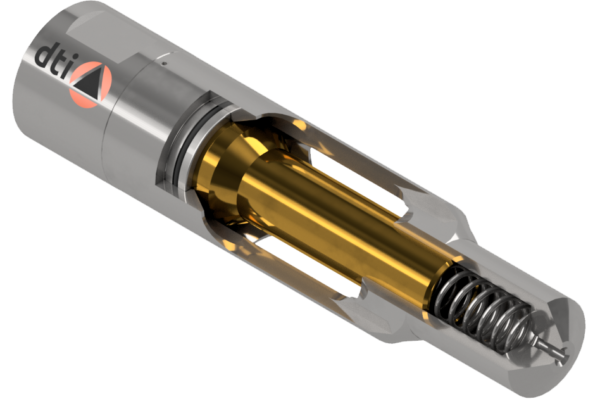

- Mechanism is locked during milling to ensure constant fluid flow to the motor.

- Adjustable hydraulic lock opens valve at desired overpressure.

- Large flow area allows very high circulation rates for effective hole cleanout.

- Valve closes easily by setting down weight.

- Robust dynamic seals and high performance treatments prolong the life of the valve.

| Part Number | OD | ID | Activation Pressure | Flow Area | Standard Connection |

|---|---|---|---|---|---|

| MCV169AA08 | 1.688" | 0.40" | 1,600-3,800 psi | 0.12 in2 | 1.00 AMMT |

| MCV212AA09-1 | 2.125” | 0.50” | 700-4,800 psi | 0.20 in2 | 1.50 AMMT |

| MCV212AA09-2 | 2.125” | 0.50” | 1,600-3,800 psi | 0.20 in2 | 1.50 AMMT |

| MCV288AA23 | 2.875” | 1.00” | 700-4,800 psi | 0.75 in2 | 2.38” PAC |

| MCV288AA23-3 | 2.875” | 1.00” | 660-3,045 psi | 0.75 in2 | 2.38” PAC |

| MCV312AA10 | 3.125” | 1.00” | 2,435-3,045 psi | 0.75 in2 | 2 3/8” REG |