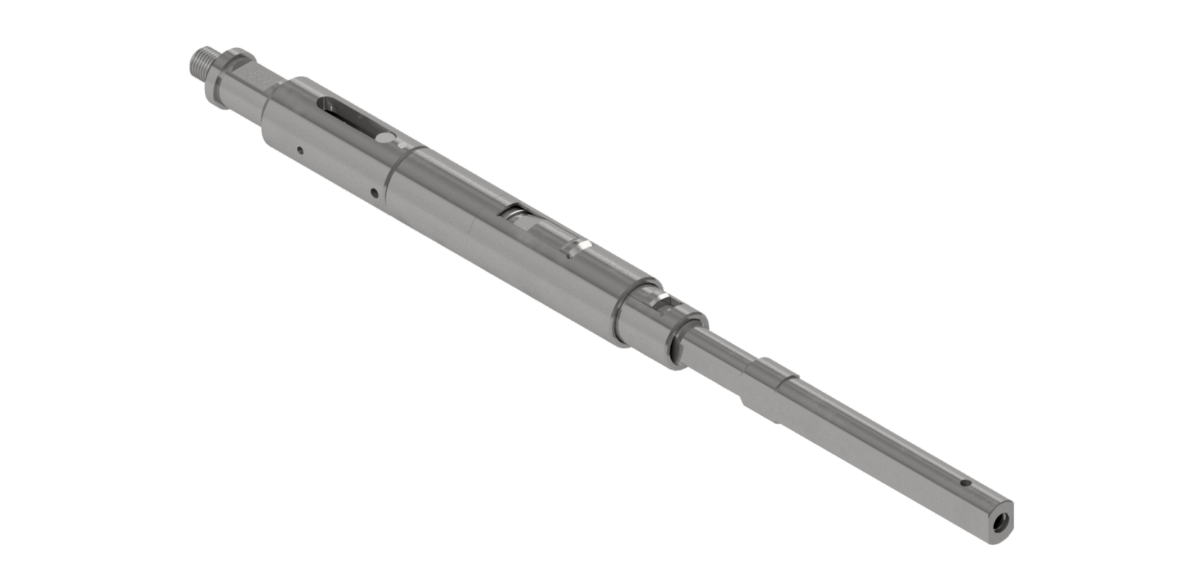

R-Line & X-Line Running Tool

FUNCTIONALITY

DEPLOYMENT

SECTORS

The DTI's X-Line and R-Line Running Tools are Slickline Deployed Mechanical Running Tools that are used to run and set DTI X or R Lock Mandrels into their respective matching nipples. The X-Line and R-Line Running Tools enable the Locks to be run with their keys retracted so that they can pass multiple selective nipple profiles and reduce the risk of hang up whilst running in hole.

The Running Tools use the proven X and R Line Running trip mechanism to move the lock keys from their retracted running position to their non-selective setting position. Once the nipple profile is located jarring down against the lock will then set the lock in to the nipple profile.

The X-Line and R-Line Running Tools can also be used for running XN and RN Lock mandrels.

Features and Benefits

- Enables the X,XN, R and RN Locks to be set on slickline.

- Utilises field proven technology.

- Robust construction.

- Flow activated versions of these tools are available.

- Lower thread in core to suit standard XX and RR Running Prongs.

| Part Number | Fish Neck | Standard Connection | Engaging Fish Neck | Lock Size |

|---|---|---|---|---|

| 171RRT | 1.188” | 15/16 UN | 1.38” (2” GS) | 1.710” R & RN |

| 188RRT | 1.375” | 15/16 UN | 1.38” (2” GS) | 1.875” R & RN |

| 212RRT | 1.375” | 15/16 UN | 1.38” (2” GS) | 2.125” R & RN |

| 218RRT | 1.750” | 15/16 UN | 1.81” (2 1/2” GS) | 2.188” R & RN |

| 231RRT | 1.750” | 15/16 UN | 1.81” (2 1/2” GS) | 2.313” R & RN |

| 256RRT | 1.750 | 15/16 UN | 1.81” (2 1/2” GS) | 2.562” R & RN |

| 312RRT | 2.313” | 1 1/16-10 | 2.62” (3 1/2” GS) | 3.125” R & RN |

| 325RRT | 2.313” | 1 1/16-10 | 2.62” (3 1/2” GS) | 3.250” R & RN |

| 343RRT | 2.313” | 1 1/16-10 | 2.62” (3 1/2” GS) | 3.437” R & RN |

| 369RRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 3.688” R & RN |

| 381RRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 3.813” R & RN |

| 412RRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 4.125” R & RN |

| 431RRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 4.313” R & RN |

| 456RRT | 2.313” | 1 1/16-10 | 4.00” (5” GS) | 4.562” R & RN |

| 587RRT | 3.125” | 1 9/16-10 | 4.75” (5 5/8” GS) | 5.875” R & RN |

| 596RRT | 3.125” | 1 9/16-10 | 4.75” (5 5/8” GS) | 5.962” R & RN |

| 188XRT | 1.375” | 15/16 UN | 1.38” (2” GS) | 1.875” X & XN |

| 231XRT | 1.750” | 15/16 UN | 1.81” (2 1/2” GS) | 2.313” X & XN |

| 275XRT | 2.313” | 1 1/16-10 | 2.31” (3” GS) | 2.750” X & XN |

| 281XRT | 2.313” | 1 1/16-10 | 2.31” (3” GS) | 2.812” X & XN |

| 331XRT | 2.313” | 1 1/16-10 | 2.62” (3 1/2” GS) | 3.313” X & XN |

| 381XRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 3.813” X & XN |

| 431XRT | 2.313” | 1 1/16-10 | 3.12” (4” GS) | 4.313” X & XN |

| 456XRT | 2.313” | 1 1/16-10 | 4.00” (5” GS) | 4.562” X & XN |