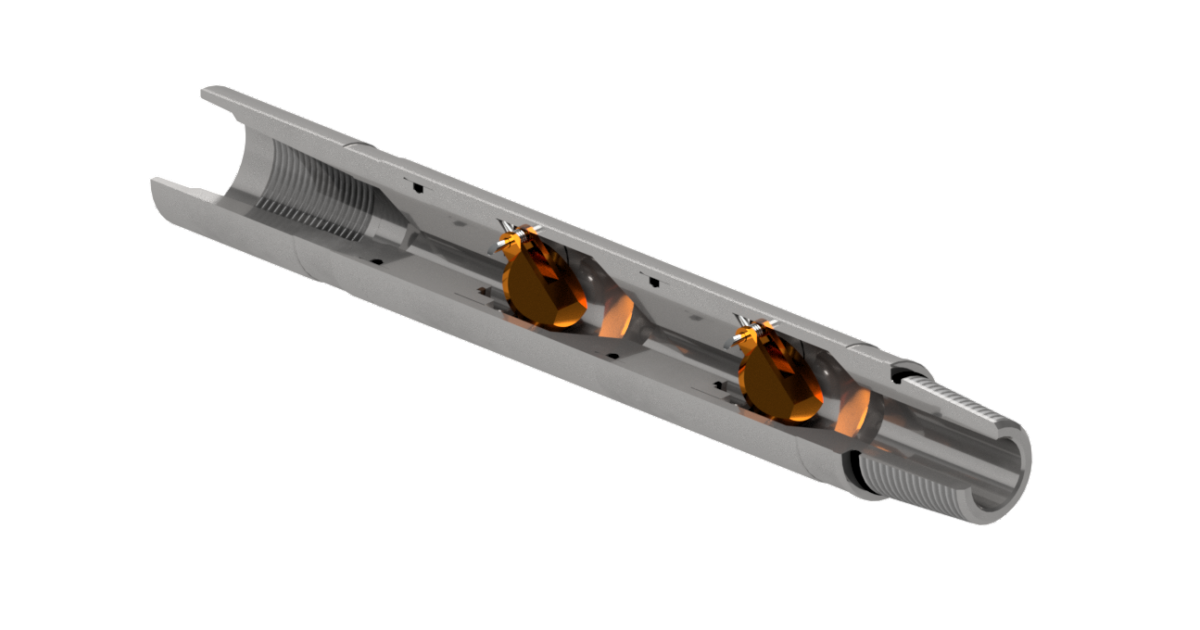

Twin Flapper Check Valve Integral Type

FUNCTIONALITY

DEPLOYMENT

Coiled Tubing

SECTORS

Oil & Gas

The DTI Coiled Tubing Twin Flapper Check Valve provides a dual barrier within the coiled tubing tool string as safety critical protection against fluid back flow. It is robust, reliable, easy to redress and rated to 10,000PSI.

The flappers are mounted integrally into the body of the tool to maximise flow area whilst providing a simple efficient and cost effective method of forming a well barrier.

The flappers have metal seating with no elastomers present and are capable of sealing at very high pressures and temperatures.

Features and Benefits

- Dual Barrier through two flapper valves.

- Metal-to metal sealing on flapper against housing.

- All Twin Flapper Check Valve Integral’s are rated to 10,000 psi and 200 C.

| Part Number | Outside Diameter | Inside Diameter | Will Pass Ball | Length | Tensile Rating | Threads |

|---|---|---|---|---|---|---|

| TFCVI100AC31 | 1.000” | 0.39” | 0.375” | 6.0” | 25,000 lbs | 0.80-12 SA |

| TFCVI150AC08 | 1.500” | 0.50” | 0.431” | 8.5” | 35,000 lbs | 1.00 AMMT |

| TFCVI169AC08 | 1.688” | 0.75” | 0.625” | 11.5” | 75,000 lbs | 1.00 AMMT |

| TFCV212AC09 | 2.125” | 1.00” | 1.000” | 12.0” | 90,000 lbs | 1.50 AMMT |

| TFCV288AC23 | 2.875” | 1.44” | 1.375” | 12.0” | 120,000 lbs | 2.38 PAC |