M-Bubble Packer

FUNCTIONALITY

DEPLOYMENT

SECTORS

Inspired by origami-engineered deployable structures from medical devices and space exploration, we are proud to unveil a groundbreaking solution for thru-tubing isolation.

Why Choose the M-Bubble from DTI?

Traditional expandable and inflatable isolation methods are often unreliable. The M-Bubble revolutionises thru-tubing isolation by offering a new level of reliability that operators can trust.

A New Era in Through-Tubing Isolation

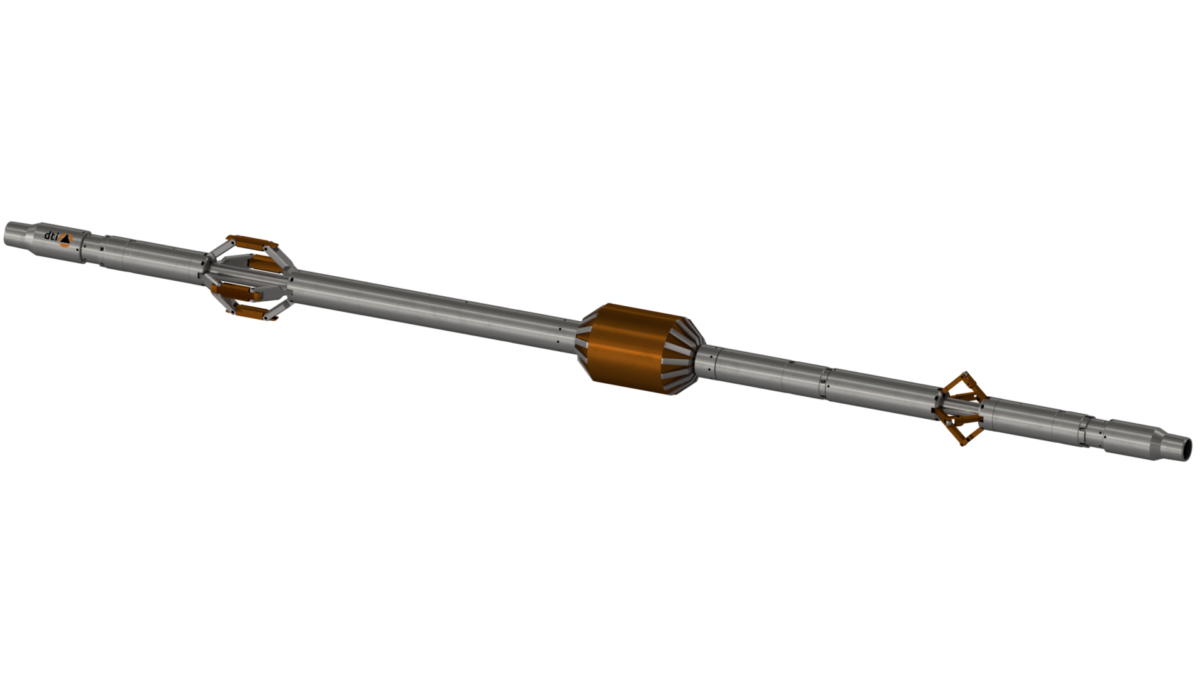

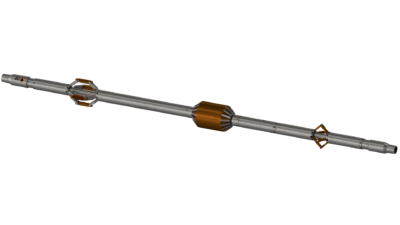

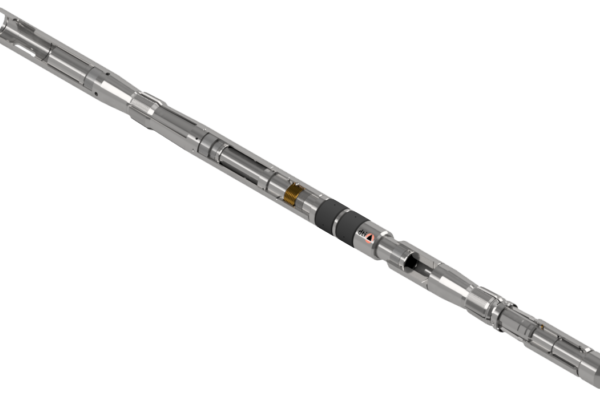

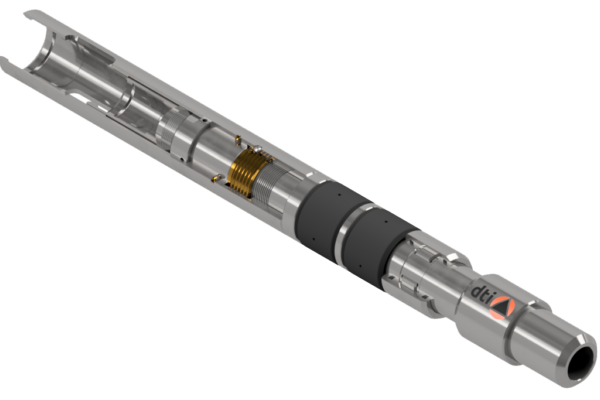

DTI’s M-Bubble Packers and Bridge Plugs incorporate an additive manufactured unfolding inconel element and are the result of four years of research and development. They offer the industry an unrivalled combination of high ID deltas (up to 300%), pressure rating and temperature rating and have an excellent track record in the field.

These products have the strength and durability for serious high-pressure sealing and can isolate pressured and flowing zones in a fast and cost-effective single run.

They help to solve a range of complex downhole plugging, sealing and isolation challenges in a variety of wells and are typically used in applications where the tool is required to pass through the completion string and set and seal in the casing or liner below. They are suitable for water shut off, zonal isolation, plug and abandonment and CCUS applications.

A standard M-Bubble Bridge Plug is designed for 2-1/8” OD tools and will set and seal in up to a 6-5/8” casing/liner. 2-5/8” OD tools will set and seal in up to a 7” casing/liner. Multiple other sizes, temperatures and pressure variants are in development.

- Unrivalled 300% expansion.

- In-flow, thru-tubing, high-pressure deployment.

- Applications include: permanent plugging, zonal isolation, cement retainer, hanger, well workover, abandonment.

- Flexibility in the design of the packers, packoffs and plugs makes the range suitable for a variety of well configurations and tubing/ casing/ liner sizes.

- They can be run on either slickline or electric line and set using powered setting tools, or run on coiled tubing and set using flow activated running tools.

Features

& Benefits

- Ultra-high expansion.

- Industry leading pressure rating + expansion ratio + ID combination.

- Expandable Inconel metal mandrel/element with NBR/ HNBR, Viton or FFKM packing element.

- Flexible deployment options with standard setting tools..

Applications

Zonal Isolation

- UHX M-Bubble Packer, Straddle Packer and Patches are suitable to isolate hydraulic fractured or perforated zones e.g. to prevent water cut.

- Can be used in high-pressure flowing wells.

- Isolated sections can vary to suit the application by stinging multiple sections of tubing into the packer or by using sections of coiled tubing.

- DTI’s UHX M-Bubble Packer can provide a means of installing isolation tubing or sand screens below the existing tail pipe.

Permanent Hanger

- The UHX Packoff allows you to create a permanent nipple profile or tag point below the upper completion for deployment of conventional plugs, injection valves or chokes.

- The UHX Packoff can be used as a hanger for the deployment of jointed tubing or coiled tubing inside and below the existing production string. This extends the life of the well by enabling the installation of velocity strings or injection strings.

Plug & Abandonment

- The UHX M-Bubble Plug provides a reliable pressure-tight barrier so that the zone below the plug can be isolated. This solution is ideal for applications where it is not possible to deposit cement, especially in cases due to the architecture of the well.

- The UHX M-Bubble Plug can be run in flowing wells and set as a platform for cement to be deposited once pressure and flow have abated. Traditional high expansion solutions do not always provide a suitable platform for cement.

Carbon Capture and Gas Storage

- UHX technology enables an existing oil and gas well to be recompleted for gas or CO2 storage.

- It provides a pressure tight platform in the liner below the upper completion and provides a profile for a temporary plug to be set prior to a well workover.

- Removing the plug enables access through the Packoff to the bore below.

| Part Numpber | Running OD | ID | Setting ID | Pressure Rating | Temp. Rating |

|---|---|---|---|---|---|

| UHX-CT275AC7029H | 2.75” | 1.20” | 6.184” (7” 29 lb/ft) | 2,000 psi | 125°C |

| UHX-CT300AA7032H | 3.00” | 1.50” | 6.094” (7” 32 lb/ft) | 2,000 psi | 125°C |

| UHX-WL320BB5018H | 3.20” | 1.50” | (5” 18 lb/ft) | 6,500 psi | 125°C |

| UHX-CT350AC5517H | 3.50” | 2.00” | 4.892” (5 ½” 17 lb/ft) | 5,000 psi | 125°C |

Other sizes and product variants are available, please contact us for more information.