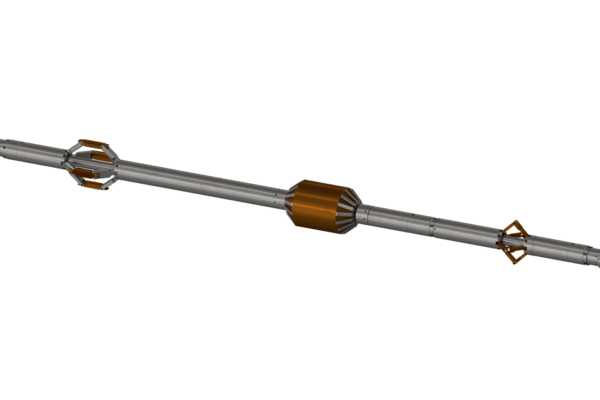

Inter-Expansion (IX) Bridge Plug

FUNCTIONALITY

DEPLOYMENT

SECTORS

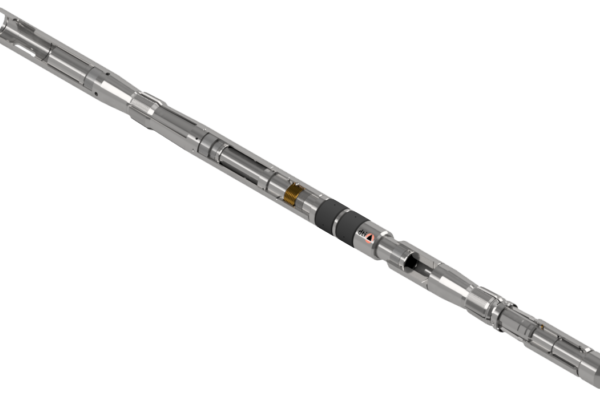

DTI’s Inter-Expansion (IX) technology provides a wide range of sealing solutions that benefit from the shortest length combined with one of the largest thru-bores in the industry. The technology boasts a unique DTI designed slip assembly to enable easier retrieval.

The IX product range offers in-flow, thru-tubing deployment in working pressures up to 5,000 psi., with an API-11D V3 rated barrier for a wide variety of applications.

At just 31” (78cm) the IX Plug facilitates a more compact and easier to handle toolstring. A shorter riser enables a wider selection of topside intervention equipment, delivering greater operational efficiency and cost savings.

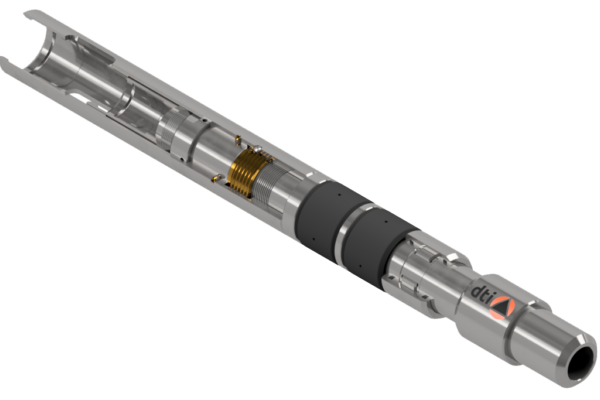

The slip assembly prevents debris ingress during deployment, then once set, the sealing element is boosted by well pressure and an integral beam spring ensures compensated packer load between the element and the slip system during pressure and temperature reversals.

The IXP can be pulled using a common pulling tool and once located within the fish neck profile, jarring up disengages the setting mechanism. As the sealing element relaxes, our unique design enables active retraction of the slips and the element gauge rings for ease of retrieval.

Suitable for use as a plug, packer, packoff, straddle, hanger or anchor, these retrievable or permanent sealing solutions can be tailored to your well application to solve a variety of complex challenges. They offer operators a fast and cost-effective method of isolating unproductive well zones, reinstating integrity, enabling enhanced oil recovery and supporting P&A operations.

Features

& Benefits

- In-flow, thru-tubing deployment.

- 5,000 psi, API 11D V3 rated.

- Shortest bridge plug in the industry.

- Large through bore (packer) variants.

- Large extrusion gap expansion range possible.

- Components rotationally locked for ease of milling.

- Simple deployment and positive retraction of slips and seal assembly for retrieval

- Permanent solution as a plug, packer, packoff, hanger, anchor or straddle.

- Suitable for zonal isolation, workover, EOR, abandonment.

Applications

Well Testing

The retrievable IX Plug provides a reliable, pressure-tight barrier so that zones can be isolated and well integrity can be tested.

Zonal Isolation

The IX Packers can be used as straddle sleeves for isolating hydraulic fractured or perforated zones that are un-productive. The length of isolated well sections can vary by stinging multiple sections of tubing into the packer or by using longer sections of coiled tubing between two packoffs. The IX Packer can provide a means of installing isolation tubing or sand screens below the existing tail pipe.

Permanent Hanger

The IX Packoff can create a permanent nipple profile or tag point below the upper completion for deployment of conventional plugs, injection valves or chokes. It can be used as a hanger for the deployment of jointed tubing or coiled tubing inside and below the existing production string, enabling you to extend the life of your well with the installation of velocity strings or injections strings.

Anchor

A polished bore receptable and a latch can provide an anchor point for the installation of an upper completion, such as a cable deployed ESP string with a pressure-controlled safety valve (also available from DTI - see below), to enable isolation above and below the packer.

| Part Number | Tubing Size | Tubing Weight | Running OD | Inside Diameter | Working Pressure | Temperature |

|---|---|---|---|---|---|---|

| IXP-PLG450AC4511H | 4 1/2" | 11.6-12.6 lb/ft | 3.600" | 1.93" | 5000 psi | 130C |

| IXP-PLG450BB4515H | 4 1/2" | 15 lb/ft | 3.600" | 1.93" | 5000 psi | 130C |

| IXP-PLG550BB5517H | 5 1/2" | 17-23 lb/ft | 4.530" | 2.85" | 5000 psi | 130C |