Upper Pump Hold Down System for Monobore Tubing

FUNCTIONALITY

DEPLOYMENT

SECTORS

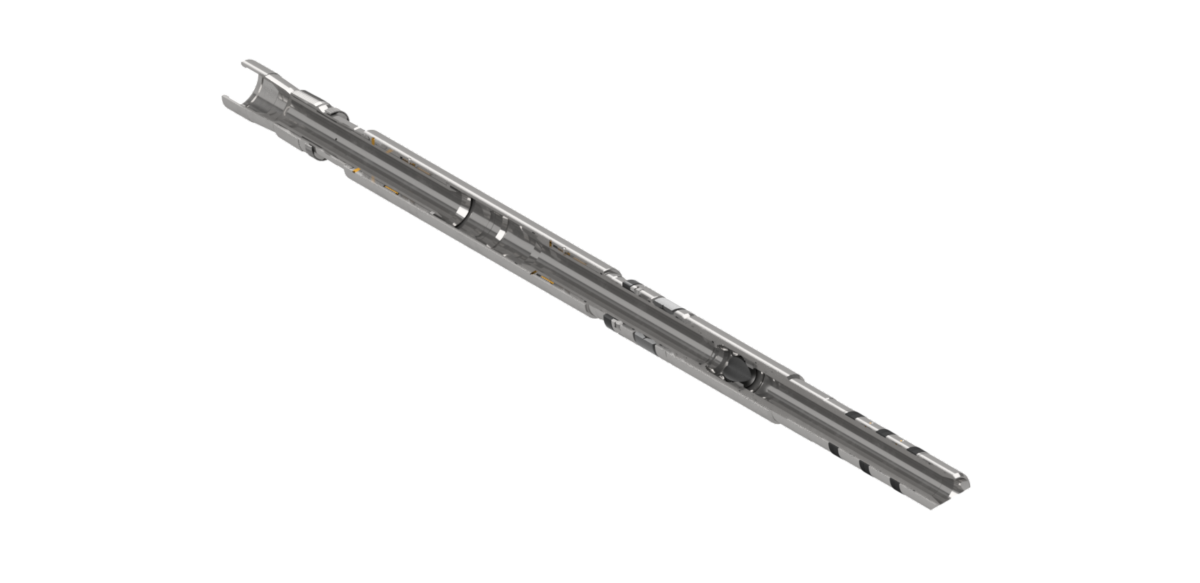

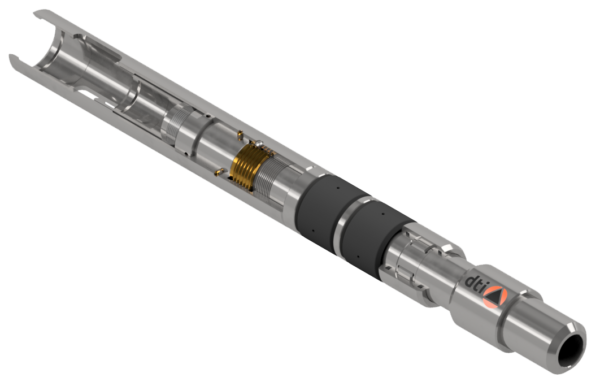

DTI's Upper Pump Hold Down System for monobore completions combines a field proven Tubing Stop, Packer, Standing Valve and stinger assembly.

The system provides a means of locating and sealing inside the Polished Bore Receptacle (PBR) of a submersible pump and holding it in position. The system provides an annular seal and stinger seal to prevent recirculation during pumping and includes a standing valve to prevent any back flow once the pumps are switched off. The hold down system can be deployed on slickline without the need for any specialist running and pulling tools.

The system can be used as an upper retainer to hold down and seal applicable artificial lift devices.

Features and Benefits

- Simple and well proven design.

- Slickline Single run set using only standard pulling tools.

- Large ID.

- DTI Field proven twin element system for sealing capability and large contact area slips to minimise damaging the casing ID.

| MODEL | OUTSIDE DIAMETER | INSIDE DIAMETER* | PRESSURE RATING | MAKEUP LENGTH** |

|---|---|---|---|---|

| 278 | 2.25” | 0.940” | 5000 psi | 60” |

| 350 | 2.72” | 1.375” | 5000 psi | 60” |

| 450 | 3.72” | 1.700” | 5000 psi | 68” |

We offer optional equipment, alternative sizes, pressure ratings, materials and thread connections. Please contact us for more information. *Without check valve. **Length depends on variant and associated equipment.