Coiled Tubing Multi-Lateral Entry System

FUNCTIONALITY

DEPLOYMENT

SECTORS

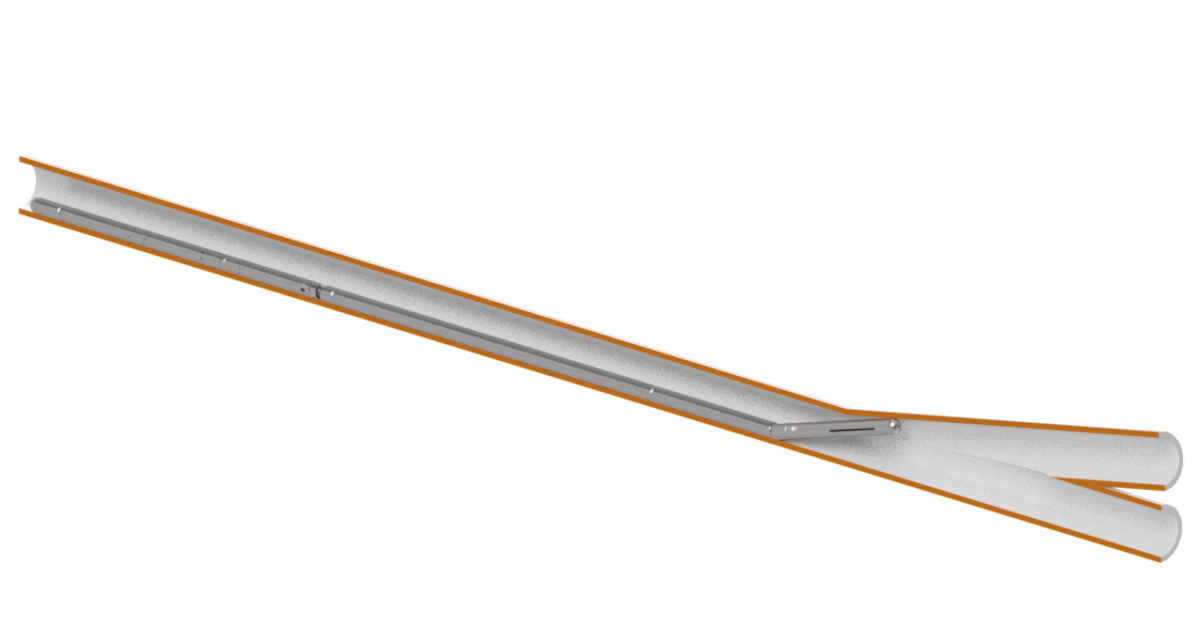

The DTI Coiled Tubing Multi-Lateral Entry System (MLES) is designed to enable the repeatable entry of the desired lateral wellbore. The system typically consists of a Torque Through Coiled Tubing Connector, a Motorhead Assembly, a High Torque Indexing Tool , a Hydraulic Knuckle Joint and a Pump Out Choke Probe.

The system is flexible and to allow multiple lateral access in a single run and to enable large volume of fluid to be pumped at high flow rates a Velocity Check Circulation Valve (VCCV) can be placed above the indexing tool and the Pump Out Choke Probe replaced with a Nozzle. To gain access to longer laterals an Extended Reach Tool can be included in the tool string.

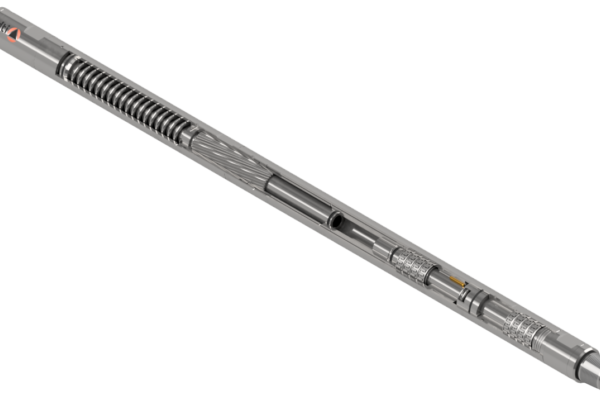

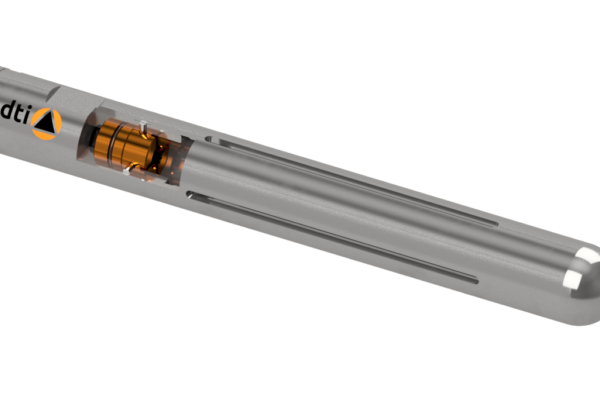

The Coiled Tubing High Torque Indexing Tool rotates the tools below it by 30° on each pressure cycle (15° and 45° indexes are available). Increasing the flow rate or pressure further activated the Hydraulic Knuckle Joint which kicks over the Pump Out Choke Probe. The length of the Probe is designed so that it will not fully articulate in the man bore unless it locates the casing window.

Typically the casing window is located by cycling the High Torque Indexing Tool and then picking up the tool string. If the window is located then the hydraulic Knuckle Joint can fully articulate and a circulation port will open. This will lead to a pressure drop giving a surface indication that the window has been located.

The DTI Coiled Tubing MLES is commonly used for multi-lateral cleanout work. A similar system is also used for acid tunnelling applications.

Features and Benefits

- The Coiled Tubing High Torque Indexing Tool ensures that the entire BHA is able to rotate or index on each cycle.

- The Hydraulic Knuckle Sub delivers a large hinge force and when fully articulated provided a reliable bleed off to produce a large observable pressure drop.

- A Velocity Check Circulation Valve can be incorporated to enable multiple lateral access together with high flow clean outs.

- Can be used in Jetting Tunnelling Applications.

- Probe Length Calculator Provided.

Applications

Logging

Controlled access of laterals enables logging tools and cameras entry to determine the condition of the lateral and use the insights to strategize the next operation.

Water Shut Off

Conventional plugs or bridge plugs can be deployed on coiled tubing into the lateral to temporarily or permanently close off the lateral if it’s no longer productive.

Clean Outs

Perhaps the most common operation for the MLES is to enable access into laterals to pump high volumes of clean out fluid such as HCl.

| Tool String Size | Indexing Tool | Hydraulic Knuckle | Pump Out Choke Probe | Velocity Check Circulation Valve |

|---|---|---|---|---|

| 1 11/16” | CIT169AC08-1 | CKJHA169AC08 | POC169AC08-18 | |

| 2 1/8” | CIT212AC09-1 | CKJHA212AC08 | POC212AC09-18 | VCCV212AC09 |

| 2 7/8” | CIT288AC23-1 | CKJHA288AC23 | POC288AC23-18 | VCCV288AC09 |

We offer optional equipment, alternative sizes, materials and thread connections. Please contact us for more information.