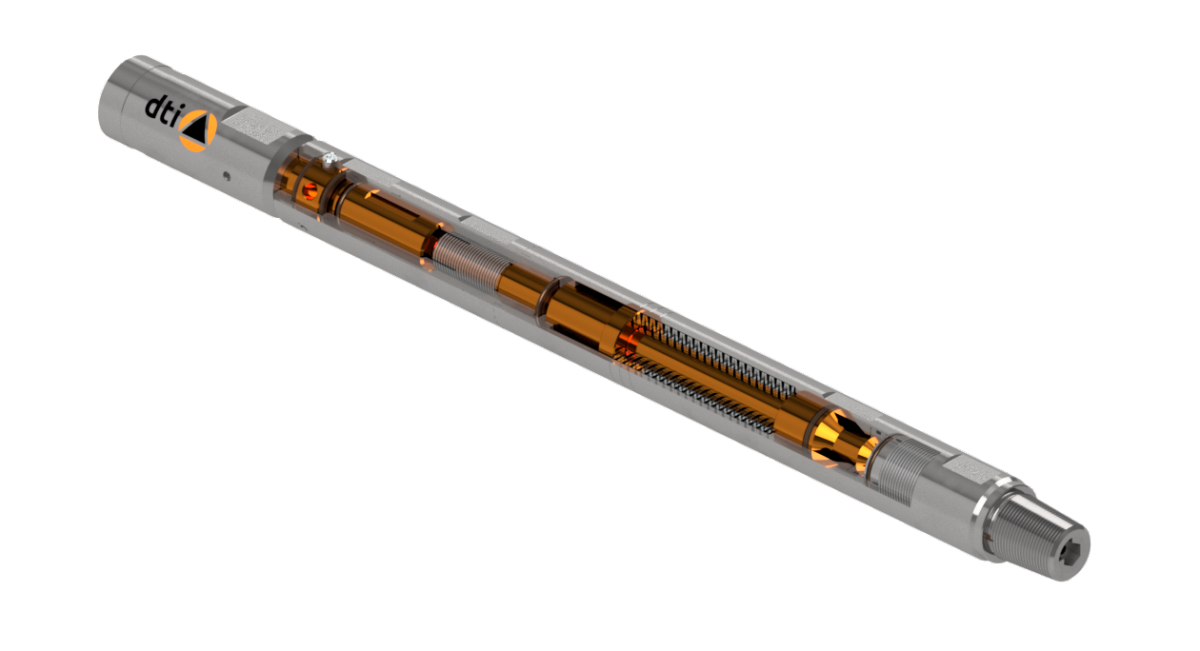

Hydrostatic Valve

FUNCTIONALITY

DEPLOYMENT

SECTORS

The DTI Coiled Tubing Hydrostatic Valve supports a column of fluid in the coiled tubing until an increase in pressure, over the pre-set opening pressure, is applied. A controlled amount of fluid is then able to be deposited in the well. Once the required volume of fluid has been pumped the pump pressure is reduced. The valve will them close, and the fluid will cease to flow through the valve.

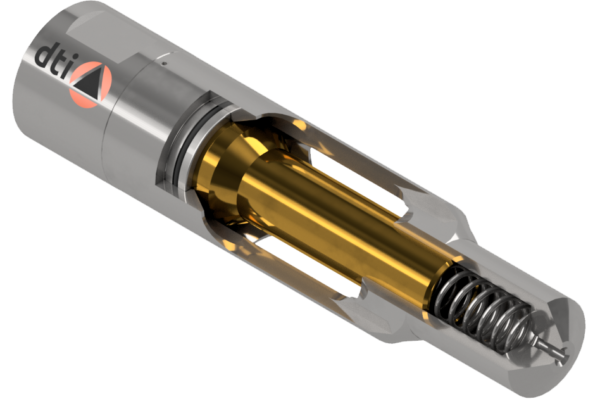

The DTI CT Hydrostatic Valve features an integral adjuster mechanism, which is activated by removing the locking screws and winding the Upper Connector sub clockwise to increase or anticlockwise to reduce pressure. This feature allows the valve opening pressure to be set without disassembling the tool or removing from the BHA.

The DTI Hydrostatic Valve locking screws also give the tool a torque through capability.

Features

& Benefits

- Easily adjust the opening pressure while in the BHA during surface testing

- Large pressure adjustment range

- Torque thru capability

- Used for placement of Cement, Acid & Solvents

- Used as a control valve for inflatable element BHA’s

- Available in H2S or standard service

| Part Number | Outside Diameter | Operating Pressure | Operating Pressure | Standard Connection |

|---|---|---|---|---|

| CCV169AC08-3 | 1.688" | 1.00 AMMT | 300-2,500 psi | 0.10 in2 |

| CCV212AC09-3 | 2.125” | 1.50 AMMT | 300-2,650 psi | 0.20 in2 |

| CCV288AC23-3 | 2.875” | 2.38” PAC | 500-4,000 psi | 0.40 in2 |

| CCV312AC23-3 | 3.125” | 2.38” PAC | 500-4,000 psi | 0.40 in2 |

We offer optional equipment, alternative sizes, pressure ratings, materials and thread connections. Please contact us for more information.