M-Bubble Bridge Plug

FUNCTIONALITY

DEPLOYMENT

SECTORS

Inspired by origami-engineered deployable structures from medical devices and space exploration, we are proud to unveil a groundbreaking solution for thru-tubing isolation.

Why Choose the M-Bubble from DTI?

Traditional expandable and inflatable isolation methods are often unreliable. The M-Bubble revolutionises thru-tubing isolation by offering a new level of reliability that operators can trust.

A New Era in Through-Tubing Isolation

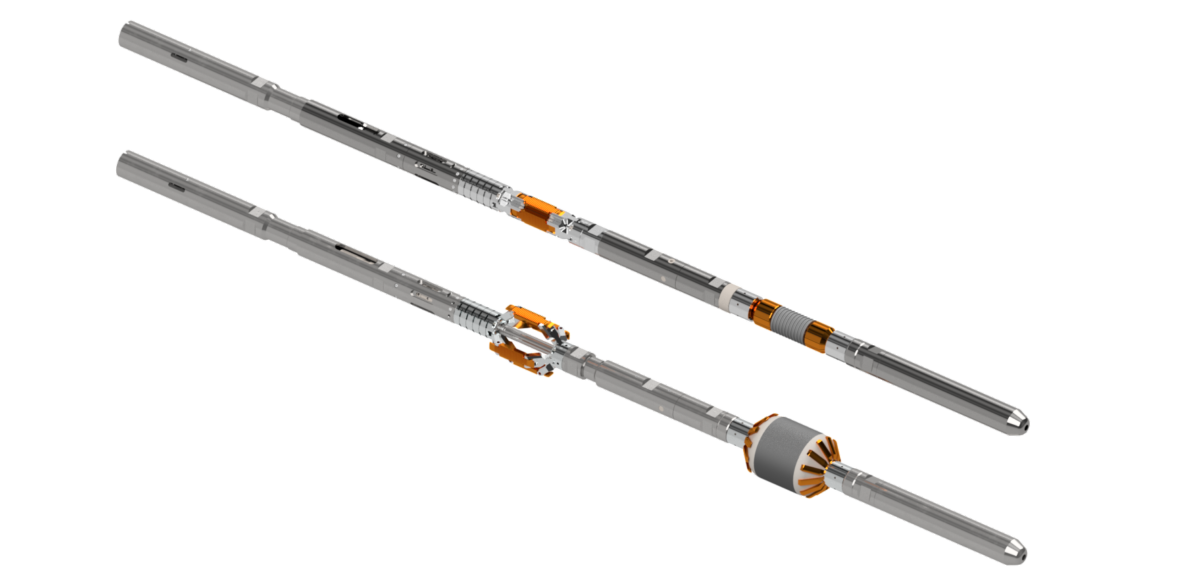

DTI’s M-Bubble Plugs and Packers incorporate an additive manufactured unfolding Inconel element and are the result of four years of research and development. They offer the industry an unrivalled combination of high ID deltas (up to 300%), pressure rating and temperature rating and have an excellent track record in the field.

These products have the strength and durability for serious high-pressure sealing and can isolate pressured and flowing zones in a fast and cost-effective single run.

They help to solve a range of complex downhole plugging, sealing and isolation challenges in a variety of wells and are typically used in applications where the tool is required to pass through the completion string and set and seal in the casing or liner below. They are suitable for water shut off, zonal isolation, plug and abandonment and CCUS applications.

A standard M-Bubble Bridge Plug is designed for 2-1/8” OD tools and will set and seal in up to a 6-5/8” casing/liner. 2-5/8” OD tools will set and seal in up to a 7” casing/liner. Multiple other sizes, temperatures and pressure variants are in development.

- Unrivalled 300% ID delta.

- In-flow, thru-tubing, high-pressure deployment.

- Applications include: permanent plugging, zonal isolation, cement retainer, hanger, well workover, abandonment.

- Flexibility in the design of the packers, packoffs and plugs makes the range suitable for a variety of well configurations and tubing/ casing/ liner sizes.

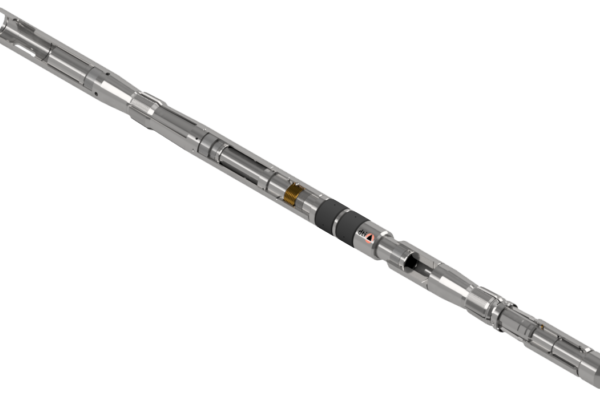

- They can be run on either slickline or electric line and set using powered setting tools, or run on coiled tubing and set using flow activated running tools.

Features

& Benefits

- Innovative Design: Utilising DTI's industry-leading expertise in additive manufacturing and our standard use of Inconel for the unfolding element ensures exceptional performance without the need for additional investment. This approach maximises efficiency by minimising waste, making it ideal for all downhole environments.

- Unmatched Performance: Achieve an industry-leading isolation solution across significant ID deltas of up to 300%.

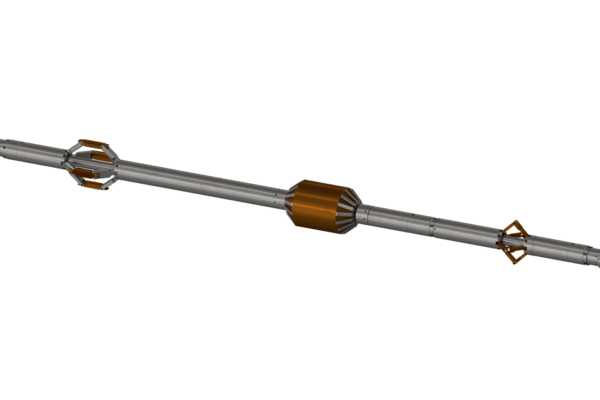

- Unique Fluted Design: Our fluted structure transitions from a compressed state to a robust 3D form through unfolding. The geometric extension follows a precise pattern determined by the initial folding configuration.

- Robust Structure: M-Bubble utilises internal hydraulic pressure to facilitate mechanical transformation. The hydraulic pressure efficiently drives the flutes into a stable spherical form without metal yielding to ensure material integrity. The M-Bubble can incorporate either a metal-to-metal seal or a labyrinth seal design to address potential tubing integrity issues.

Applications

Water Shut Off

The M-Bubble is ideal for water shutoff and effectively eliminates unwanted water production, offering a step change in consistency and reliability. By extending well life, significantly reducing water processing costs and optimising production, this solution empowers operators with a reliable way to shut off water in mature wells.

Plug and Abandonment

The deployment of M-Bubble as an abandonment plug is via wireline or coil tubing and significantly reduces ABEX associated with workover rig use. It enables a smaller equipment footprint, reduces POB and potentially eliminates the need to pull tubing.

Carbon Capture & Gas Storage

M-Bubble Bridge Plug technology enables an existing oil and gas well to be recompleted for gas or CO₂ storage. The M-Bubble provides a pressure tight platform in the liner below the upper completion to remove the requirement for kill fluids.

A variation on the permanent M-Bubble Bridge Plug enables unsetting and removal by pushing down the well.

| Part Number | Running OD | Setting ID | Pressure Rating | Temp. Rating |

|---|---|---|---|---|

| MB-WL175AD4513V | 1.750” | 3.826” (4 ½” 13.5 lb/ft) | 1,000 psi/ 2,600 psi | 150°C |

| MB-WL213BB2592V | 2.125” | 2.992” (3 ½” 9.2 lb/ft) | 5,000 psi | 150°C |

| MB-WL213BB4011V | 2.125” | 3.476” (4” 11 lb/ft) | 4,500 psi | 150°C |

| MB-WL213BB4512V | 2.125” | 3.958” (4 ½” 12.6 lb/ft) | 4,500 psi | 150°C |

| MB-WL213BB5015V | 2.125” | 4.408” (5” 15 lb/ft) | 3,500 psi | 150°C |

| MB-WL213BB5517V | 2.125” | 4.892” (5 ½” 17 lb/ft) | 3,500 psi | 150°C |

| MB-WL213BB6624V | 2.125” | 5.920” (6 5/8” 24 lb/ft) | 500 psi | 150°C |

| MB-WL263BB7023V | 2.625” | 6.366” (7” 23 lb/ft) | 2,000 psi | 150°C |

| MB-WL263BB7026V | 2.625” | 6.276” (7” 26 lb/ft) | 2,000 psi | 150°C |

| MB-WL263BB7026V | 2.625” | 6.276” (7” 26 lb/ft) | 2,000 psi | 150°C |

| MB-WL263BB7029V | 2.625” | 6.184” (7” 29 lb/ft) | 2,000 psi | 150°C |

| MB-CT213BB5517V | 2.125” | 4.892” (5 ½” 17 lb/ft) | 3,500 psi | 150°C |

| MB-CT250BB6624V | 2.500” | 5.920” (6 5/8” 24 lb/ft) | 2,000 psi | 150°C |

Other sizes and product variants are available, please contact us for more information.