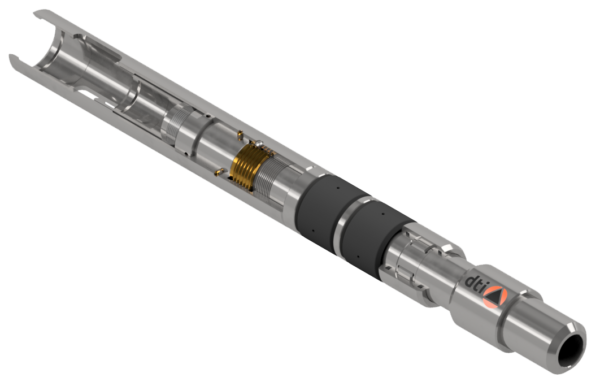

PKO Tubing Packer

FUNCTIONALITY

DEPLOYMENT

SECTORS

The DTI PKO Packer is a flow control tool used to seal inside production or injection tubing. The large ID makes this tool suitable for applications such as tubing patches, straddle sleeves and hanging flow control valves.

The DTI PKO Packer is designed to be run, set and retrieved from the tubing using conventional wireline well intervention methods.

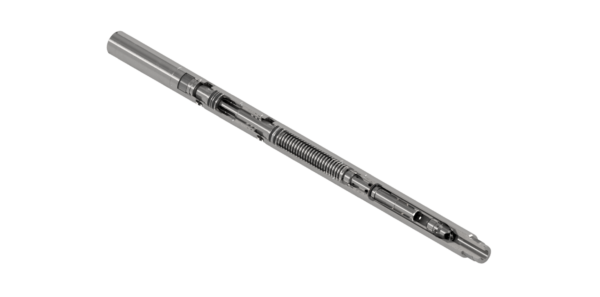

The DTI PKO Packer is comprised of a lower slip which is set first and acts as a stop to set the seal element pack-off assembly, which is assembled in combination with a segment housing that acts to centralise the tubing seal elements within the tubing when energised and the upper slip mechanism.

When being run as an upper packer in a straddle system or against a tubing stop the lower slip mechanism is not required.

The packing element assembly is designed to provide a long life, whilst also ensuring that the DTI Tubing Packer can be retrieved from the well when required.

Features and Benefits

- Can be deployed and pulled on slickline.

- 5000 psi rated.

- Large through bore.

- Can be configured to form part of a straddle isolation sleeve or act as a hanger.

- The top sub can incorporate a polished bore receptacle.

- The bottom sub can incorporate a seal stinger assembly.

Applications

Zonal Isolation

The PKO Packer can be used as part of a straddle isolation system for isolating hydraulic fractured or perforated zones that are un-productive.

Hanger

The PKO Packer can be set in the tubing and incorporate a nipple profile or tag point below the upper completion for deployment of conventional plugs, injection valves or chokes. It can be used as a hanger for the deployment of jointed tubing or coiled tubing inside and below the existing production string, enabling you to extend the life of your well with the installation of velocity strings or injections strings.

Pump Hold Down System

A polished bore receptable and a latch can provide an anchor point for the installation of an upper completion, such as a cable deployed ESP string. A DTI Slim Pump Safety to enable isolation above and below the packer can also be included in the completion.

| Part Number | Tubing Size | Setting ID | Bore | Working Pressure |

|---|---|---|---|---|

| 238PKO-XXX | 1.85” | 2 3/8” 4.6 lb/ft | 0.63” | 5,000 |

| 278PKO-XXX | 2.25” | 2 7/8” 6.4 lb/ft | 0.85” | 5,000 |

| 350PKO-XXX | 2.86” | 3 ½” 9.2 to 10.2 lb/ft | 1.75” | 5,000 |

| 450PKO-XXX | 3.72” | 4 ½” 12.6 lb/ft | 2.38” | 5,000 |

We offer optional equipment, alternative sizes, pressure ratings, materials and thread connections. Please contact us for more information.